Electric Motor Automatic Armature Production Line

group nameArmature production line

-

Min Order1 piece

brand nameNIDE

modelND-ZZX-6

payment methodL/C, T/T

-

update timeTue, 25 Oct 2016 14:16:29 GMT

Paramtents

Certification CCC

Name armature production line

Function produce armatures

Condition New

Automation High automation

Packging & Delivery

Min Order1 piece

Briefing

Detailed

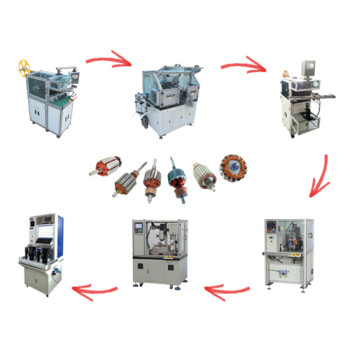

This automation rotor manufacturing assembly line is consisted of serval machines, including insulation paper insertier, rotor winder, commutator welding machine, wedge inserter, and rotor testing machine. This production line is equipped with mechanical arm which will carry the rotor and transfer it to the next station.

Applications:

It is suitable for power tooling motor armature production, especially with agreat production valume.

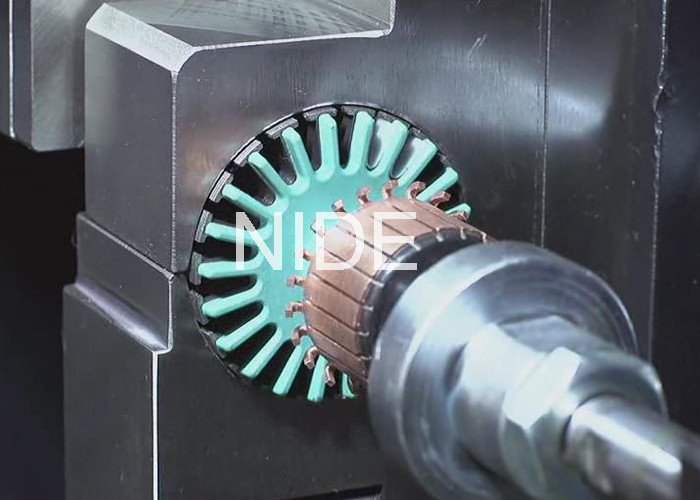

Insluation paper inserting machine

This machine is used to inserting paper into rotor slot. The insulationmaterial can be as per customer's requirement, DMD,DM, polyester film are all can be used in this machine.

Rotor winding machine

After doing paper inserting machine, mechanical arm and converyorwill carry the rotor the rotor winding machine position. The machineis equipped with touch screen and PLC, winding parameter could be set andmodified on the screen.

Commutator welding machine

It can weld both riser and hook type commutators. This machine is applied to DCmotor and universal motor. It is controlled by PCL, all the data setting can bedone on the touch sreeen. There are four power control method, namely secondaryconstant current, secondary constant voltage secondary constantfrequency.

Wedge inserting machine

The wedge material can be as per customer's requirement, DMD,DM, polyester film are all can be used in this machine.

Rotor testing machine

It is suitable for testing less than 72 segments armature. The Voltagewithstand test time could be set as per different requirements. Testingitems could be screened.Testing data saved automatically, and could be tracedand printed at any time

Information needed for rotor production line inquiry

It will be better if customer could send us detailed drawing including belowinformation.

1. Rotor lamination drawing

2. Rotor assemble drawing

3. Rotor stack drawing

4. Rotor winding diagram drawing: with rotor wire diameter and turn number

5. Commutator drawing

6. Shaft drawing

7. Required residual unbalancing volume and initial unbalancing volume

8. Wedge and insulation paper material

9. Required productivity

10. Other technical requirement

If possible, it will be better if customer can send us samples.

You need a product

You May Like

- Nearest port for product export

- SHANGHAI, NINGBO

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C

- Export mode

- Have the independent export and import right