molding silicon rubber

- US $12.30

200 - 40,000 kilogram

- US $6.98

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelmolding silicon rubber of HY625# HY638# HY718# HY7

payment methodT/T, L/C, Westem Union

-

update timeTue, 05 Nov 2013 11:22:48 GMT

Paramtents

color of molding silicon rubber white

Certificate of molding silicon rubber SGS , MSDS, RoHS, Reach ,ISO9001:2000,

Shape of the molding silicon rubber molding silicon rubber in liquid shape

Shelf Life of the molding silicon rubber 18 month

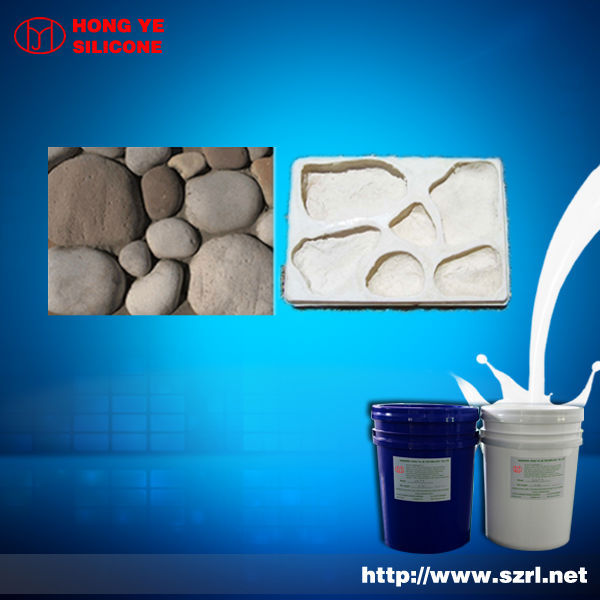

molding silicon rubber applicaiton For molds making

package of the molding silicon rubber Vacuum Pumping

Sanple free of cost

catalyst 3% free of cost

MOQ 200 kg

delivery within 3 days after payment confirmed in our bank

Packging & Delivery

Min Order200 kilogram

Briefing

a light viscosity and easy operation.,

b large duplication times

c good tear strangt

Detailed

Molding Silicon Rubber

Introduction of molding silicon rubber:

Molding silicon rubber is a kind of liquid fluid, features good fluidity and good operation., large duplication times

Features of molding silicon rubber :

1.molding silicon rubber with Good characteristics of easy-operation

2.molding silicon rubber with features of Ligh viscosity and good flowability

3.molding silicon rubber with features of Low shrinkage

4.molding silicon rubber with features of Favorable tension

5.molding silicon rubber with features of No deformation

6.molding silicon rubber High temperature resistance,

7.molding silicon rubber acid and alkali-resistance

8.molding silicon rubber with features of ageing resistance

Operations of molding silicon rubber:

Step One: Take 100g of part A and add 2g of part B and mix the molding silicone rubber and curing agent evenly.

Step Two: vacuum pumping

Without exception, this step takes less than 10 minutes. Otherwise, it will cause , and no more further steps will be available

Step Three: Perfusion Molding

The perfusion molding is an easy way to make molds, it’s Slowly and evenly perfuse the mixed molding silicon rubber into the square frame. After the cross linking reaction.

Why isn’t the molding silicon rubber mold acid & alkali and aging resistant?

It is due to the addition of the silicon oil into the molding silicon rubber . Normally we do not advise our customers to add any silicon oil into the molding silicon rubber. If it is necessary, the ratio must be 5%-10%.

For getting further information about molding silicon rubber, PLS contact with Miss Caroline

Tel: +86-755-89948019

Mobile: +86-18938867567

Skype: cathy19900719

Email: hysf(at)szrl(dot)net

Website : www(dot)szrl(dot)net

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents