hot molding silicone

- US $8.98

200 - 40,000 kilogram

- US $6.89

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY620# 640# 628# 638# silicon rubber

payment methodT/T, L/C, Westem Union

-

update timeTue, 05 Nov 2013 11:39:29 GMT

Paramtents

Color Any color is available

Certificate ISO9001,SGS

application for sculpture,resin craft ,etc

MOQ 200kg

Payment T/T L/C Western union

Package 25kg/drum 200kg/drum

Features Liquid

Port Shenzhen

Packging & Delivery

Min Order200 kilogram

Briefing

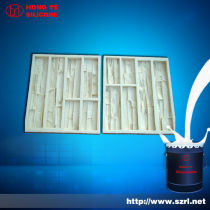

1 for plaster mold making

2 for rock mold

3 for column

4 for resin

Detailed

hot molding silicone application

1. molding silicne is used for sculpture, toys, gifts

2. molding silicne is used for decoration, plate engrave

3. molding silicne is used for resin crafts, unsaturated resin crafts

5. molding silicne is used for poly resin crafts, candle crafts, plastic crafts

6. molding silicne is used for plaster crafts, Bunddhist statue crafts, etc.

hot molding silicone features

A. Workability

The base compound and curing agent are mixed and then poured into the mold to create a silicone rubber mold quickly. Workable time and cure time can be adjusted.

B. Mold-releasability

The cured rubber releases easily from the mold, so mold-release agents (soapy water, wax, etc.) are unnecessary.

C.Dimensional stability

These rubbers offer good dimensional stability, with little shrinkage.

D. Flowability

They have excellent flowability, so the original form is reproduced accurately. This includes even intricate shapes and details such as fingerprints and wood grain.

E.Heat and chemical resistance

These rubbers have outstanding resistance to heat and chemicals.

F.Deep-section curability

Moldmaking RTV silicone rubber compound cures uniformly throughout the mold, regardless of thickness

G.Non-exothermic

No heat is generated during curing, meaning no adverse effects to the original.

hot molding silicone date sheet

Silicone rubber (HY-625) for mold making

Model | Appearance | Viscosity (cs) | Hardness (Ao) | Tensile Strength (kgf/c) | Tear Strength (kgf/) | Elongation (%) | Mixing ratio(%) | Operating Time(H) | Curing Time(H) |

625 | White | 14000~16000 | 25~28 | ≥35 | ≥25 | ≥500 | 2~3 | 0.5 | 2~4 |

molding silicone for sculpture FAQ

1. Why does the mold made of silicone rubber have an unsmooth surface with tracks and strips on it?

It is due to product or model to be molded should hasn't been sanded or polished . If the mold or product is not sanded or polished, the mold made of whatever quality silicone rubber will not be good and smooth enough since the mold or the product itself is not smooth or perfect. Another case is that uneven brushing of the release agent will also bring about unsmoothness of the mold.

Any question abt hot molding silicone pls free to ask Ms. Christy

Tel: 86-755-89948006

Mobile:86- 18938867547

Fax: 86-755-89948030

Email:hyxj(at)szrl(dot)net

Skype:christyxu911

You need a product

Related Searches

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents