Liquid molding silicone for PU molds

- US $7.20

200 - 40,000 kilogram

- US $5.80

40,001 - 999,999 kilogram

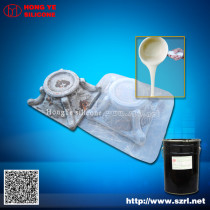

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY 728#

payment methodT/T, L/C, Westem Union

-

update timeTue, 05 Nov 2013 11:41:55 GMT

Paramtents

CAS No. 3910

Other Names silicon rubber

MF pratA+partB

Type rubber raw material

COLOR WHITE

Mixing Ratio 10:1

Appearance Fluid

Certificated RoHS, Reach, MSDS,SGS.ISO9001:2008

Sample Available

Port Shenzhen

Packging & Delivery

Min Order200 kilogram

Briefing

features: good elongation

Detailed

liquid molding silicone applications

Application of Liquid molding Silicone rubber

Liquid Silicone rubber for mold making is primarily intended for poly resin crafts, PU crafts, PU resin crafts ,gypsum crafts ,unsaturated resin crafts, lighting and candles crafts ,plastic toy , stationery gifts crafts industry, a large statue Buddha, furniture, furniture decorative materials, statues Buddha, artifacts copied, building decoration materials, large-scale cement mold, artificial fossils Factory, Europe component factory, simulation landscapes, animals and plants sculpture, sandstone crafts and so on.

Liquid molding Silicone rubber for mold making description

Silicone rubber for mold making is white or red flowing liquid with general hardness of 22-50A°after curing. Molding silicon rubber is a kind elastic silicon rubber mold which features with resistance to deformation, high-temperature, acid-alkali and expansion as well as high reproduction times, good tensile strength, tear strength and elongation.

The solutions of the sticky of the Liquid silicone mold?

The main reason for this problem is that you do not handle the products or original molds well, then you should deal with the original mold or products carefully before molding. Such as for the products with a complicated

pattern or a unsmoothed surface, you should polish and clean the products after which it will be molded ,then spray the release agent. Normally, the release agent can be Vaseline , detergent. liquid wax Etc. In practical process, you can bush different release agent according to different material.

The second reason is that the operator pour the silicone into the mold when the mixture is mixed evenly, then the finish silicone mold will not cure and dry entirely..

For more information, please feel free to contact with Ms Sabrina

Tel:+86075589212382

Mobil:+8618938867574

Email:hyse(at)szrl(dot)com

Skype:sabrina369488

Web site:http://www(dot)szrl(dot)net

Sabrina will be at your servce any time

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents