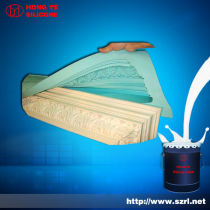

RTV molding silicone rubber for concrete baluster moulds making

- US $7.80

200 - 40,000 kilogram

- US $5.40

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY 628 silicon rubber,HY silicone rubber 630

payment methodT/T, L/C, Westem Union

-

update timeTue, 05 Nov 2013 11:47:24 GMT

Paramtents

Shaping Mode Silicone Mould

Product Material Rubber

Product Vehicle Mould

Color white

Certificate RoHS, MSDS, SGS, ISO9001:2000

Sample free

Catalyst 4% free available

Demould time( hrs) 4-6

Pot life (mins) 40-60

MOQ 200 KG

Packging & Delivery

Min Order200 kilogram

Briefing

1.resistance to deformation

2.good tensile strength

3.low shrinkage

4.high reproduction

Detailed

RTV molding silicone rubber for concrete baluster moulds making

RTV molding silicone rubber applications

Mold silicon rubber silicone rubber is

mainly applied for making various molds,such as reproduction of

poly resin, epoxy, polyurethane-polymer, plaster, gypsum, soaps, candle & lighting, architecture,

decorative arts and crafts, plastic toy, gift and stationery, big statue, cultural relic product, etc..

RTV molding silicone rubber features description

The manual mold silicon rubber features with the resistance to deformation, good tensile strength as well as low shrinkage, and time of reproduction determined on the basis of customers.

RTV molding silicone rubber operations

Firstly process and prepare the model mold or the product to be duplicated, take certain amount of the silicon rubber, add 2-3% solid curing agent, and mix evenly and they are ready for use. One pair of mold can be solidified and formed in 2-3 hours.

(Note: our company does not recommend you to add silicon oil. If a special soft silicon mold or fine detailed and complex patterns products are required, 5%-10% silicon oil can be added to soften the mold for easy demold.)

FAQs in the use of the operations

What should we do when the air bubbles appeared in the process of mold making ?

To handle this situation depends on different cases. Under the condition of an available vacuum pumping machine, mix the silicone rubber and curing agent evenly and then take it to vacuum chamber to deair. If without a vacuum pumping machine, reduce the amount of the curing agent properly. For example, change the mixing ratio of the silicone rubber and the curing agent from former 4% to 1%-2%. In this way, the pre-crosslinking time of silicone rubber will slow down, so, the air in the mold will be eliminated gradually to reduce the air bubbles.

Any questions, please feel free to contact Orianna (sales manager):

Phone:0086-755-89311348

FAX: 0086-755-89948030

MOBILE:0086-18938867545

E-mail: hyyg(at)szrl(dot)net

skype:orianna317

Website: http://..........net

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents