RTV molding silicone for casting

- US $7.28

200 - 40,000 kilogram

- US $5.50

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

model628#

payment methodT/T, L/C, Westem Union

-

update timeTue, 05 Nov 2013 12:30:14 GMT

Paramtents

CAS No. 63148-62-9

Other Names silicone molding

Grade Standard Industrial Grade

Purity 98%

Appearance semi-liquid

Application molding

color white

Packging & Delivery

Min Order200 kilogram

Briefing

Detailed

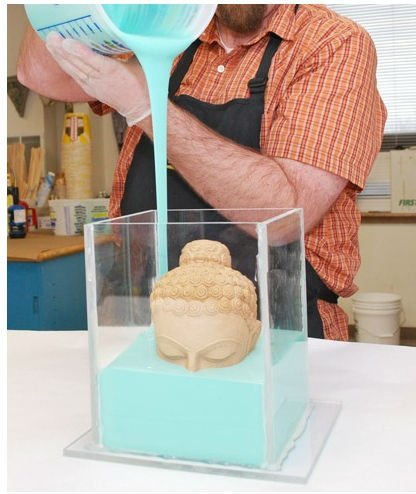

Molding silicone for casting

1Two part of Molding silicone for casting application:

Molding silicone for casting is mainly be used for mold making for poly resin crafts,Pu crafts, Pu resin Crafts, gypsum/ plaster moldings, light and candle crafts, Statues and , cement, concretes and so on

2Two part of Molding silicone for casting Features :

1) Resistance to deformation and expansion

2) Low shrinkage

3) Excellent molding times.

4) Easy operation

5) Low viscosity . good fluidity

6) High molding times

3.Operations of Molding silicone for casting

If the customer wants to make large products and large size molds, the mold should be made ofsilicon rubber for mold making with high hardness. On the contrary, if the mold with fine and precision patterns, it should be made of silicon with low hardness. The amount of the curing agent depends on the actual requirements of the customer.

Operations of Molding silicone for casting

Step One: Take 100g of part A and add 2g of part B and mix the silicon rubber and curing agent evenly.

Notes: Moulding silicone for casting is a kind of flowing liquid and it contains two parts. Part A is a kind of white flowing liquid and part B is the curing agent. Remember to mix part A and part B evenly, otherwise the silicon rubber will be partly solidified and this will give birth to difficulties in your final operation. What’s more, the finished moulds will meet a short life. All of these will cause a waste of silicon rubber.

Step Two: vacuum pumping

Without exception, this step takes less than 10 minutes. Otherwise, it will cause cross linking reaction, and no more further steps will be available.

Step Three

For more information , pls feel free to contact

Ms Sabrina

Tel:+86075589212382

Mobil:+8618938867574

Email:hyse(at)szrl(dot)com

Skype:sabrina369488

Web site:http://www(dot)szrl(dot)net

You need a product

Related Searches

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents