Easy Opeartion Liquid Silicone Rubber for Molding

- US $12.89

200 - 40,000 kilogram

- US $7.88

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelrtv silicone E630#

payment methodT/T, L/C, Westem Union

-

update timeTue, 05 Nov 2013 13:33:19 GMT

Paramtents

Available color Translucent RTV silicone mold making rubber

Certifications RoHS.MSDS.SGS ISO9001:2000

Operation way brushing way

Hardness 30 shore A

Curing time 20 - 30min

Mixing proportion of curing agent 1:1

Operating time 20-30min

Viscosity (MPas -25 0C) 30000 ± 5000(part A),5000 ± 500(part B)

Tensile-strength(kgf /cm2 ) 80 ± 5

Packging & Delivery

Min Order200 kilogram

Briefing

Hight strength and light viscosity

High reproduce times

Free catalyst

SGS

Detailed

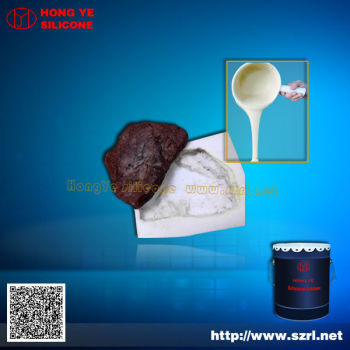

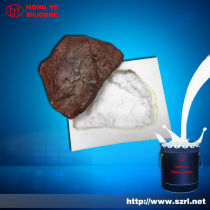

Liquid Silicone Rubber for Molding

Liquid Silicone Rubber for Molding is generally named two-components silicone rubber, Part A is a flowable liquid, part B is the curing agent. It features an exceptional fluidity and good operability. The mixing ratio is 1:1,mainly be suitable for making stone molds application.

1.Mainly application of Liquid Silicone Rubber for Molding

Liquid Silicone Rubber for Molding is a two part silicone rubber and curing with tin catalyst. As with a low viscosity,high tear strength and excellent duplication times,it's widely used for concrete casting,cement products casting,Making silicone rubber molds for artificial stone,concrete crafts,cement crafts,GRC/GPR decorations casting.

2.Features of Liquid Silicone Rubber for Molding

a.low viscosity

b.easy operation

c.long shelf life over 12 months

d.high strength and low shrinkage

e.curing at room temperature within 2-4hours

f.high duplication times and no deformation

TDS of Liquid Silicone Rubber for Molding E630#

Model | HY-E630# |

Appearance | Translucent |

Mixing Ratio | 1:1 |

Operating time (Mins 25°C) | 30 - 40 |

Curing time (Mins 25°C) | 3-4h |

Hardness (A°) | 30±2 |

Density ( g/cm 3 ) | 1.08 |

Viscosity (CS) (Part A) | 30000 ± 5000 |

Viscosity (CS) (Part B) | 5000 ± 500 |

Viscosity (CS) (After mixed) | 10000 ± 2000 |

Tensile-strength( kgf /cm2 ) | 100 ± 20 |

Tear-strength (kgf /cm2 ) | >15 |

Elongation-break(%) | 500 |

Retractility(%) | ≤0.1 |

3.The solutions of the sticky of the silicone mold?

The main reason for this problem is that you do not handle the products or original molds well, then you should deal with the original mold or products carefully before molding. Such as for the products with a complicated

pattern or a unsmoothed surface, you should polish and clean the products after which it will be molded ,then spray the release agent. Normally, the release agent can be Vaseline , detergent. liquid wax Etc. In practical process, you can brush different release agent according to different material.

The second reason is that the operator pour the silicone into the mold when the mixture is mixed evenly, then the finish silicone mold will partialy cured.

4.How to making stone mold with Liquid Silicone Rubber for Molding ?

Mixing:

Select a mixing container 4-5 times larger than the total volume of material to be mixed.

Weigh out the selected silicon rubber and catalyst. Stir for several minutes scraping the

sides and bottom of the container carefully to produce a homogeneous mixture. When

using power mixers, avoid excessive speeds, which could entrap large amounts of air or

cause overheating of the mixture, resulting in shorter pot life.

The air entrapped in the mixing step needs to be removed to eliminate voids in the cure

product. This can be done by exposing the material to a vacuum of 10-20 mbar. The

material will expand, crest and reduce to about the original level. Degassing is usually

complete about two minutes after frothing ceases.

Curing:

After mixing the two parts combination, the material will cure at room

temperature. Selection of the Beta will determine cure speed, the work life as well as the

demoulding time.

The system is sensitive to changes in heat and humidity and therefore variations in cure

speed may be seen if one or both variables are changed.

Handling and Safety Material Safety Data Sheets are available upon request.

SHELF LIFE:Twelve (12) months from date of shipment when stored at 24°C in original unopened packages.

PACKAGE:Packed in clean 20kg/pail, 200kg/pail.

Any questions about Silicone Rubber, Leah is at your service.

TEL: 086-755-89212382

FAX: 086-755-89948030

MOBILE: 086-189 3886 7561

Website: www(dot)szrl(dot)net

E-MAIL: hyji(at)szrl(dot)net

Skype: leahchou1214

QQ: 189 3886 7561

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents