good electrical insulator white silicone coatings roofing materials

- US $12.56

200 - 40,000 kilogram

- US $7.65

40,001 - 999,999 kilogram

group nameAddition cure silicone rubber

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelTB3140

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 18:01:56 GMT

Paramtents

Main Raw Material Other

Usage Appliance Paint,Building Coating,Paper Coating,Plastic Coating,Rubber Coating,textiles coating

Application Method Brush

State Liquid Coating

Model TB3140

Appearance Transparent

Hardness(shore A) 40±2

Mix ratio(A:B) 1:1

Viscosity(mPa.s) 60000~100000

60000~100000 4.6

Tear-strength(KN/m) 19±2

Elongation(%) 360

Pot life/working time(25°C) 12-24 hours

12-24 hours 10~20(mins)

Packging & Delivery

Min Order200 kilogram

Briefing

Detailed

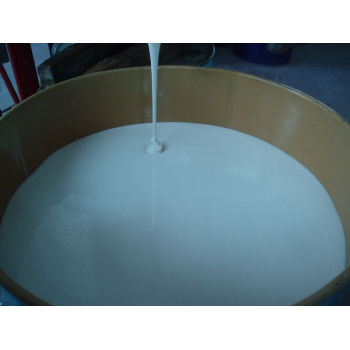

good electrical insulator white silicone coatings roofing materials

TB3140 Silicone Rubber For Coating Textiles is a 2-part liquid silicone with high transparency, great tear-strength and strong bonding force. This product portfolio is

complemented by water-based finished silicone rubber dispersions and a large number of special additives for customizing our standard grades. Textile coaters will thus find the perfect solution for every application at HY SILICONES.

Application:

It is specially used for skid-proof purpose of frilals, underclothes and widely applied for cotton fabric, polyester-mixed cotton cloth, nylon cloth, flax, woolen, insulating cloth, building coating etc.

Specification:

-Low shrinkage(<0.1%)

-Good skid-proof effect and high adhesive strength

-Wearproof, wash-resistant, high temperature resistant

-Non-toxic and odorless, food grade silicone

-High transparency and good tear-strength.

Datasheet:

Model | TB3140 |

Appearance | Transparent |

Hardness(shore A) | 40±2 |

Mix ratio(A:B) | 1:1 |

Viscosity(mPa.s) | 60000~100000 |

Tensile strength(Mpa) | 4.6 |

Tear-strength(KN/m) | 19±2 |

Elongation(%) | 360 |

Pot life/working time(25°C) | 12-24 hours |

curing time(100-120°C) | 10~20(mins) |

Operation introduction:

1,Mix Part A and Part B as ratio 1:1, you may add additive such as pigment as ratio 1~2% into part A.

2,It can be cured by heating with 100~150 degree, the curing time will be 5~10 minutes.

SHELF LIFE:

8-10 months when stored under 24°C in original unopened packages.

PACKAGE:

If ratio is 1:1 :Packed in 20kg/pail + 20kg/pail and 200kg/pail + 200kg/pail.

If ratio is 10:1 :Packed in 20kg/pail + 2kg/pail and 200kg/pail + 20kg/pail.

Why Silicone?

People often ask how silicone differs from conventional roofing materials. It may look and feel similar to some plastics, but it is a fundamentally different material with many unique and desirable characteristics.

Silicone is a man-made material based on the element silicon. Chemists and industrialists have been developing and exploring the many properties and applications of silicone for over 80 years. There are numerous forms of silicone including gels, oils, greases, adhesives, sealants and rubber. We will focus on silicone rubber, a polymer, and one of the most popular forms of silicone.

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents