Electronic encapsulation silicone rubber for electronic board

- US $12.88

200 - 40,000 kilogram

- US $9.88

40,001 - 999,999 kilogram

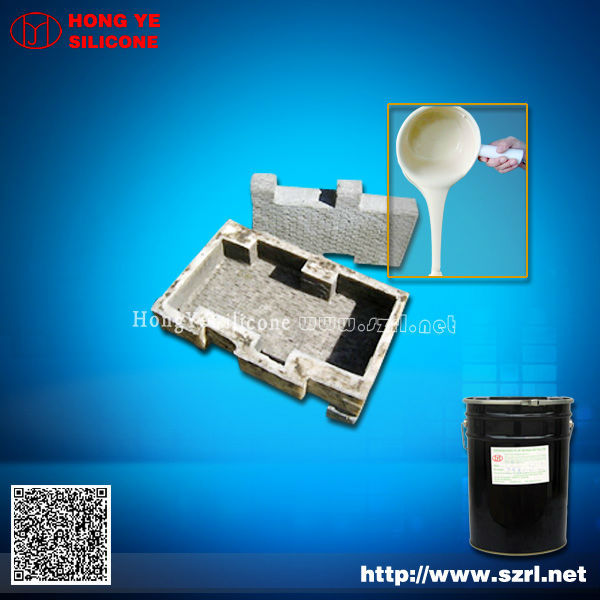

group nameelectronic potting silicone rubber

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY9055# 9060# silicone rubber

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 19:31:08 GMT

Paramtents

MOQ 200kg

FOB Price US$ 12.58-17.74

Payment T/T L/C Western union

Color Any color

Package 25kg/drum 200kg/drum

Port shenzhen

Features liquid

Certifications RoHS, MSDS, SGS, ISO9001:2000

Packging & Delivery

Min Order200 kilogram

Briefing

Low shrinkage

Favorable tension

No deformation

good tear strength

Detailed

Product Feature of encapsulation silicone 9060

HY-9060# is a kind of low viscosity, Inherent flame resistance, two components addtion cured potting silicone with heat-conducting. It cures with both on room temperature and heated temperature. It has the feature of the higher temperature the faster of the curing time. It can be applied to electronic components for insulation, waterproofing, fixed and flame retardant. The flame retardant UL94-V0 level can be achieved. It mainly applied in electronic components surface with materials of PC(Poly-carbonate),PP,ABS,PVC, etc. and metal materials.

Typical Application of encapsulation silicone 9060

HY-9060# is suitable for

- high powered electronics,

- DC/DC module and circuit board which requires heat dissipation and high temperature resistance.

It can be broadly used for LED screen, Wind Power Generator, PCB substrate, etc.

Technical Parameters of encapsulation silicone 9060

Features | Part A | Part B | |

Before Curing | Appearence | Gray Fluid | White Fluid |

Viscosisty(25°Ccps) | 3000±500 | 3000±500 | |

Operation features | Mixing Ratio | 1:1 | |

Viscosisty(after mixing) (cps) | 2500~3500 | ||

Operating Time(25°C hr) | 120 | ||

Curing time (min,25°C) | 480 | ||

Curing time(80°C hr) | 20 | ||

After Curing | Hardness(Shore A) | 60±5 | |

Thermal conductivity [W(m·K)] | ≥0.8 | ||

Dielectric Strength(KV/mm) | ≥25 | ||

Permittivity(1.2MHz) | 3.0~3.3 | ||

Volume Resisivity(Ω·cm) | ≥1.0×1016 | ||

linear expansibility [m/(m·K)] | ≤2.2×10-4 | ||

Fire Resistance | 94-V0 | ||

(Pls note: the above data for this product in 25 °C temperature, 55 percent humidity conditions, for reference. The accurate data is measured by customers to when using.)

TECHNICAL GUIDELINES for encapsulation silicone 9060

1, Pls put part A and part B in separate container and stir evenly before mixing the two part together.

2, Weight Ratio: part A: part B = 1:1

3, Deaeration the mixture in vacuum pump under 0.08 MPa for 3-5 minutes.

4, The temperature influences the curing time of HY-9060#. When in too low temperature, we suggest customers appropriately heat the mixture to accelerate vulcanization. Suggested operation time and temperature. With temperature of 80~100°C, the silicone will cure in 15 minutes, while in 25°C room temperature, the silicone will cure around 8 hours.

Warm Tips of RTV silicone for electronic encapsulation:

1.The following material may hinder the curing of the product, So pls apply after summary experiment. When necessary, pls clean the application areas.

Condensation silicone which not completely cured or organic tin compounds

Sulphur, sulfide and sulfur rubber materials.

Amine compounds as well as contains the amine materials.

Pewters solder flux.

2. Should be sealed storage.The mixture should be used up at once, avoid causing waste.

3. Silicone belongs to non-dangerous goods, but keep away from mouth and eyes.

4. When it gets stratified after a period of storage, Please mix 9060 evenly before using, it does not affect the performance

Any more information abt Electronic encapsulation silicone rubber , pls feel free to contact Ms.Bella

Mobile: 0086-18938867572

Tel: 0086-755-89948006

Fax: 0086-755-89948030

Website: www (dot) szrl (dot) net

Email:hysi(at)szrl(dot)net

Skype: bellajiaqi

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents