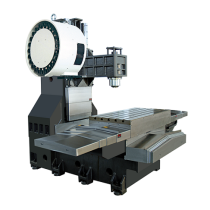

VMC850P VERTICAL MACHINING CENTER

group nameVERTICAL MACHINING CENTER

-

Min Order1 piece

brand nameSINO CNC MACHINERY

payment methodL/C, T/T

-

update timeFri, 26 Apr 2019 13:53:09 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

ITEM | | DETAILS | |||||||

1 | WORKTABLE(WIDTH×LENGTH) | mm | 500×1000 | ||||||

2 | T SLOTS | mm | 5-18 | ||||||

3 | DISTANCE BETWEEN T SLOTS | mm | 100 | ||||||

4 | MAX.LOAD BEARING OF WORKTABLE | kg | 500 | ||||||

TRAVEL | |||||||||

5 | X AXIS | mm | 850 | ||||||

6 | Y AXIS | mm | 500 | ||||||

7 | Z AXIS | mm | 550 | ||||||

8 | DISTANCE FROM COLUM TO SPINDLE CENTER | mm | 582 | ||||||

9 | DISTANCE FROM TABLE TOP SURFACE TO SPINDLE NOSE | mm | 100-650 | ||||||

SPINDLE | |||||||||

10 | SPINDLE HOLE TAPER | BT40 | |||||||

11 | SPINDLE SPEED RANGE | r/min | 20-8000 | ||||||

12 | MAIN MOTOR MODEL | βiI12/ 10000 | |||||||

13 | SERVO MAIN MOTOR RATED POWER | kw | 11 | ||||||

14 | SERVO MAIN MOTOR 30MINS POWER | kw | 15 | ||||||

15 | SERVO MAIN MOTOR RATED OUTPUT TORQUE | Nm | 52.5 | ||||||

16 | SPINDLE PART DYNAMIC BALANCE TYPE | G1 | |||||||

17 | SPINDLE ACCURACY | SPINDLE FACE RUNOUT::0.005mm | |||||||

SPINDLE RADIAL RUNOUT :NEAR-END 0.007mm | |||||||||

TOOLS HOLDER SIZE | |||||||||

18 | TOOLS HOLDER STANDARD | MSA403 BT40 | |||||||

19 | RIVET STANDARD | MSA403 P40T-1 | |||||||

FEED | |||||||||

20 | X/Y FEED MOTOR MODEL | βiSC 12/3000 | |||||||

21 | X/Y FEED MOTOR MAX.SPEED | r/min | 3000 | ||||||

22 | X/Y FEED MOTOR RATED POWER | kw | 1.8 | ||||||

23 | X/Y FEED MOTOR RATED OUTPUT TORQUE | Nm | 11 | ||||||

24 | Z AXIS FEED MOTOR MODEL | βiSC 22B/2000 | |||||||

25 | Z AXIS FEED MOTOR MAX SPEED | r/min | 2000 | ||||||

26 | Z FEED MOTOR RATED POWER | kw | 2.5 | ||||||

27 | Z FEED MOTOR RATED OUTPUT TORQUE | Nm | 20 | ||||||

28 | X/Y FEED RATE | m/min | 48/48 | ||||||

29 | Z FEED RATE | m/min | 32 | ||||||

30 | CUTTING FEED SPEED | mm/min | 10000 | ||||||

TOOL MAGAZINE | |||||||||

31 | TOOLS MAGAZINE MODEL | MANIPULATOR | |||||||

32 | CAPACITY | pcs | 24 | ||||||

33 | FULL TOOLS MAX TOOL DIAMETER | mm | Ф78 | ||||||

34 | NEIGHBOR EMPTY TOOL DIAMETER | mm | Ф120 | ||||||

35 | MAX.TOOLS ALLOWABLE WEIGHT | kg | 8 | ||||||

36 | MAX.TOOLS ALLOWABLE LENGTH | mm | 300 | ||||||

37 | TOOL CHANGE TIME | s | 2.5 | ||||||

38 | TOOL CHANGE WAY | FORWARD/REVERSAL | |||||||

POWER SOURCE | |||||||||

39 | MACHINE ELECTRIC CAPACITY | KVA | 20 | ||||||

40 | COOLING PUMP FLOW RATE | L/min | 40 | ||||||

41 | MACHINE COMPRESSED AIR | kg | 6~8 | ||||||

42 | POWER REQUIREMENT | 380V±10% 50Hz | |||||||

ENVIRONMENTAL REQUIREMENT | |||||||||

43 | ENVIRONMENTAL TEMPERATURE REQUIREMENT | 0℃~40℃ | |||||||

44 | RELATIVE HUMIDITY | 20%~80% | |||||||

MACHINE SIZE | |||||||||

45 | MACHINE DIMENSION | mm | 2460×2355×2860 | ||||||

46 | MACHINE WEIGHT | kg | 5500 | ||||||

47 | MACHINE SHIELD | FULL PROTECT | |||||||

ACCURACY | |||||||||

48 | X/Y/Z POSITION ACCURACY | mm | ±0.008 | ||||||

49 | X/Y/Z RE-POSITION ACCURACY | mm | ±0.004 | ||||||

2.2 STANDARD ACCESSORIES

CODE | PART NAME | MANUFACTURER | MODEL |

1 | CONTROL SYSTEM | FANUC | FANUC 0i MF |

2 | SERVO FEED MOTOR | ||

3 | SPINDLE SERVO MOTOR | ||

4 | DRIVE | ||

5 | SPINDLE UNIT | ROYAL / VYUCHENG | BT40-φ150 |

6 | BALL SCREW | PMI | 4016/4016/4016(C3) |

7 | LINEAR SLIDE WAY | PMI | 35/45/45 |

8 | SPINDLE BEARING | NSK | 7014/7014 |

9 | TOOL CYLINDER | HINAKA | 4.5t |

10 | TOOL MAGAZINE | OKADA / POJU | 24T |

11 | LOCKNUT | YINSH | YSF M30x1.5P |

12 | COUPLING | MIKI PULLEY | SFC-060DA2 |

13 | HEAT EXCHANGER | WENHENG | EA-05N |

14 | BALL SCREW BEARING | NTN | BST30*62-1BP4 |

15 | REDUCING VALVE | MINDMAN | MAFR300L-10A-D |

16 | DIGITAL PRESSURE GAUGE | CKD | JAPAN |

17 | AUTOMIZED LUBRICATOR | MINDMAN | MAL300L-10A |

18 | ELECTRIC LUBRICATION PUMP | ISHAN | TAIWAN |

19 | OIL FILTER | ISHAN | TAIWAN |

20 | SPINDLE PULLEY | GATES | 8YU-856-8M-40 |

21 | ELECTRIC PARTS | SCHNEIDER / TE |

Note: Due to production flexibility, there may be some change on parts brand for above list, but we promise all the brands are all top brand to ensure the same quality.

OTHERS | |

X/Y/Z LINEAR SLIDE WAY | OIL-WATER SEPARATION |

PRE-TENSION FOR BALL SCREW | SPINDLE AIR SEALING |

RIGID TAPPING | AUTO LUBRICATION SYSTEM |

WORKPIECE COOLING SYSTEM | RS232 INTERFACE |

M30 AUTOMATIC POWER-OFF SYSTEM | PORTABLE BLOWING DUST AIR GUN |

ELECTRICAL CABINET HEAT EXCHANGER | MANUAL PULSE GENERATOR |

ALL OVER PROTECTION SHIELD | ANCHOR BOLTS AND PADS |

You need a product

You May Like

- Nearest port for product export

- SHANGHAI, NINGBO

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C

- Export mode

- Have the independent export and import right