Wood plastic composition WPC machine PP PE WPC profile Machine Manufacturer

group namePP PE WPC Profile Machine

-

Min Order1 set

brand nameHEGU

modelSJMS65/132

payment methodL/C, T/T

-

update timeWed, 02 Dec 2020 15:18:07 GMT

Paramtents

Product name Double step WPC extrusion machine by using PP/PE w

Motor power 37KW

Screw material Bimetallic

Barrel Material SKD

Packging & Delivery

Weight25000.00kg / set

Min Order1 set

Briefing

1, use 30%PP PE plastic recycle

2, 70% wood powder

3, turnkey project solution

Detailed

1, Preparing the material:

wood powder material: 80-100mesh wood powder, it can be made from wood sawdust, rice husk, rice straw, wheat husk and straw, cotton staw and agriculture wastage. machine need is wood crushing and pulverizer machine

plastic material: recycled PP/PE plastic after washing and crushing into flakes. machine need is plastic washing and crushing line.

3, WPC products extrusion-molding

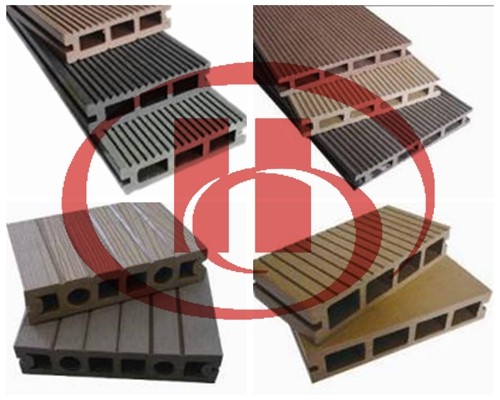

Extrusion and molding:Our conical double screw extruder is specially designed for high quality WPC products extrusion, it can make WPC material fully mixed and melted and uniform,equip with good deisgned mold and calibration, online cutting device, our Wood plastic WPC profile machine can make good WPC products, such as decking prodfiles, garden profiles, chair profiles, pergoza profiles, railing system profiles.

4, WPC product Surface treatment processing machine:

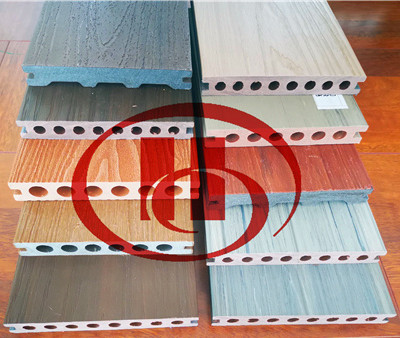

sanding, brushing and embossing process can make the WPC products with nature wooden grain which is good accepted by customers.

2, Material: uses PVC,PP,PE resin or recycled plastic and plant fibre ( wood powder,chaff,straw etc.) as raw material.

3, Advantages: This kind of wood-plastic are not only very similar with natural wood in appearance and feel, but also have the same characteristics as wood of excisable, planeable,sawable, unmatched grip,low bibulous rate, good moisture resistance, mothproof,mildew resistance,good resistance to acid and alkali,anti-corrosion, and it has the feature of fire resistance. The products are non-toxic,non-polluting,environment-friendly and save-energied, without formaldehyde, benzene and ammonia and other harmful substances.

4, Application: The wood-plastic products are widely used in outdoor floor, close to water construction,balcony,landscape architecture,chairs and benches, fences, interior doors and windows, furniture, etc.

You need a product

You May Like

- Nearest port for product export

- Qingdao Port, China, Any port, China

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash