PE WPC co-extrusion material China Wood Plastic WPC Machine Manufacturer Hegu WPC machinery

- US $4.00

1 - 100 kilogram

- US $3.90

101 - 1,000 kilogram

- US $3.80

1,001 - 3,000 kilogram

- US $3.60

3,001 - 10,000 kilogram

- US $3.30

10,001 - 25,000 kilogram

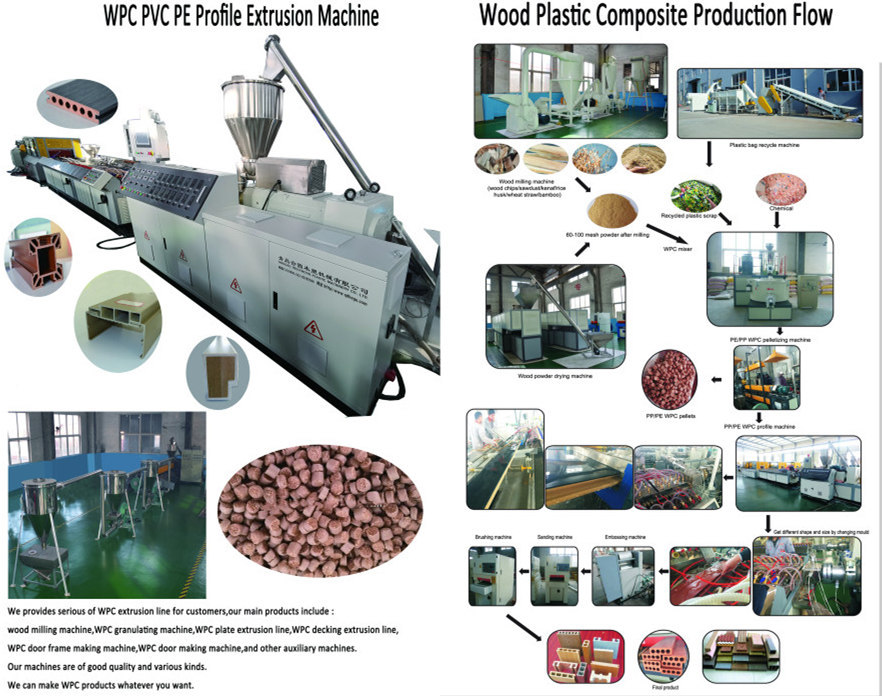

group namePP PE WPC Profile Machine

-

Min Order1 kilogram

brand nameHEGU

modelHG-300

payment methodL/C, T/T

-

update timeMon, 29 Mar 2021 09:49:43 GMT

Paramtents

wood plastic composite machine WPC decking co-ectrusion machine

WPC profile machine co-extrusion

Application Outside landscape

Packging & Delivery

Weight1.00kg / kilogram

Min Order1 kilogram

Briefing

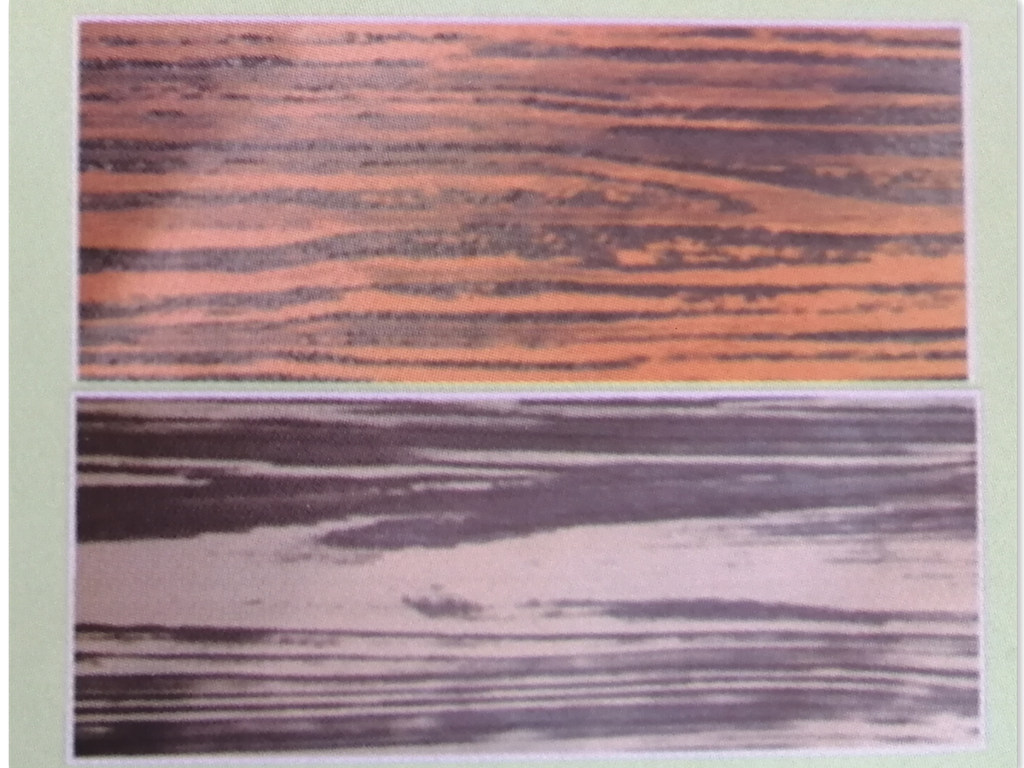

1,self-colored co-extrusion material

2,Base color master

3,Wood grain color master

Detailed

Qingdao HEGU has long been engaged in the research and development of the co-extrusion materials ,its production and manufacturing technical for co-extrusion WPC.Our aim is to provide service and create win-win cooperate based on mutual benefits.

|

Exposure time

|

L*

|

a*

|

b*

|

E* | Grey scale |

|

720 hours

|

-0.14

|

0.11

|

0.18

|

0.26 | 5 |

|

2000hours

|

-0.37

|

0.18

|

0.43

|

0.60 | 4.5 |

|

3000hours

|

0.35

|

-0.20

|

-0.27

|

0.48 | 4.5 |

4000hours | 0.54 | -0.22 | -0.31 | 0.66 | 4.5 |

|

Test Method

|

Test Results

|

|

EN15534-1:2004 section 7.5

|

Brinell hardness:79Mpa Rate of elastic recovery :54% |

|

EN15534-4:2004 section 4.5.7

|

You need a product

You May Like

- Nearest port for product export

- Qingdao Port, China, Any port, China

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Cash