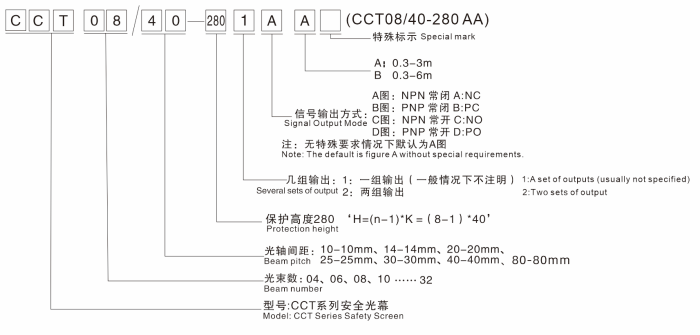

Safety light curtain sensor for machine protection bending machine

group nameCCT universal safety light curtain sensor

-

Min Order1 piece

brand nameCYNDAR

modelCCT

payment methodT/T, PayPal

-

update timeSun, 21 Feb 2021 21:41:07 GMT

Paramtents

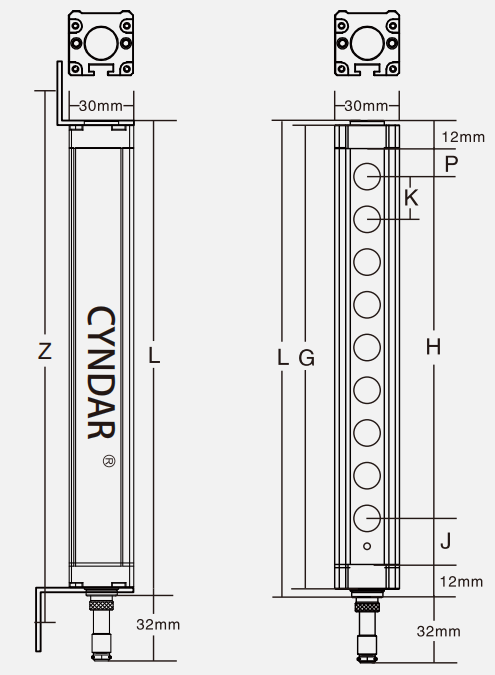

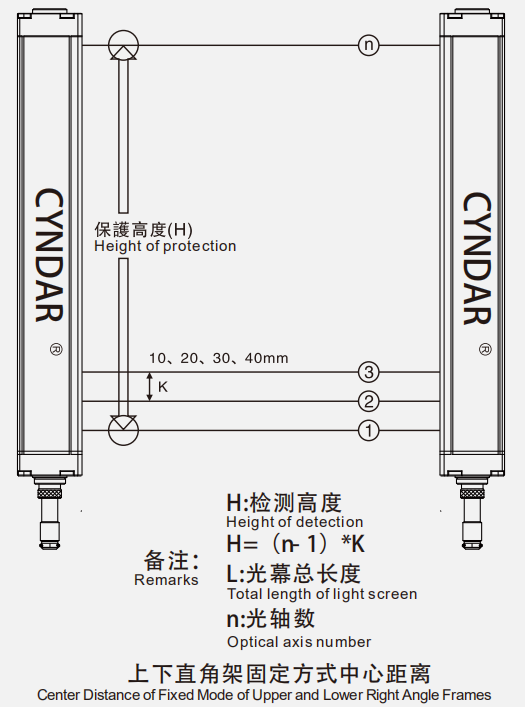

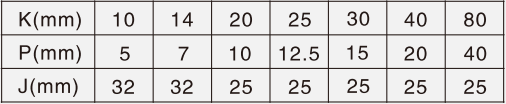

Optical axis spacing 10-40MM

Detection accuracy 18-47MM

Light curtain form Opposite

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Fault self-check: ir light curtain adopts original imported components. Using dual-loop output signals, it can automatically detect possible faults in the circuit and output alarm signals. According to this principle, the safety light curtain will not send out control output signals that cause safety hazards when the synchronization signal error, infrared light emission drive circuit failure, poor cable contact, abnormal power supply voltage, CPU error and other faults occur, so as to ensure protection The safety of the object. Therefore, the design principle of smart scan safety light curtain gives the fault self-check function;

1. Determination of the height of the protected area. The height of the protected area refers to the effective protected area.

2. The protection height of the machine tool should not be less than: the stroke of the machine tool slide + the adjustment amount. For other machinery or dangerous areas, choose the light curtain safety device of the corresponding specification according to the height of the area to be protected.

You need a product

You May Like

6YRS GZ Cyndar Co., Ltd

- Delivery clauses under the trade mode

- FOB, EXW, Express Delivery

- Acceptable payment methods

- T/T, PayPal