scaffolding galvanized steel pipe

group nameScaffolding tube

-

Min Order25 metric ton

brand nameBossen steel

payment methodL/C, D/A, D/P, T/T, Western Union, MoneyGram

-

update timeFri, 11 Sep 2015 11:44:16 GMT

Paramtents

Standard ASTM, BS, GB, JIS, ASTM A53-2007, BS 1387, GB/T3901, JIS G3444-2006

Grade A53-A369, Q195-Q345, A53(A,B), Q195, Q215, Q235, Q345

Thickness 2 - 4 mm

Section Shape Round

Outer Diameter 33.4 - 60.3 mm

Secondary Or Not Non-secondary

Application Structure Pipe

Technique ERW

Certification ISO ,CE

Surface Treatment Galvanized

Packging & Delivery

Min Order25 metric ton

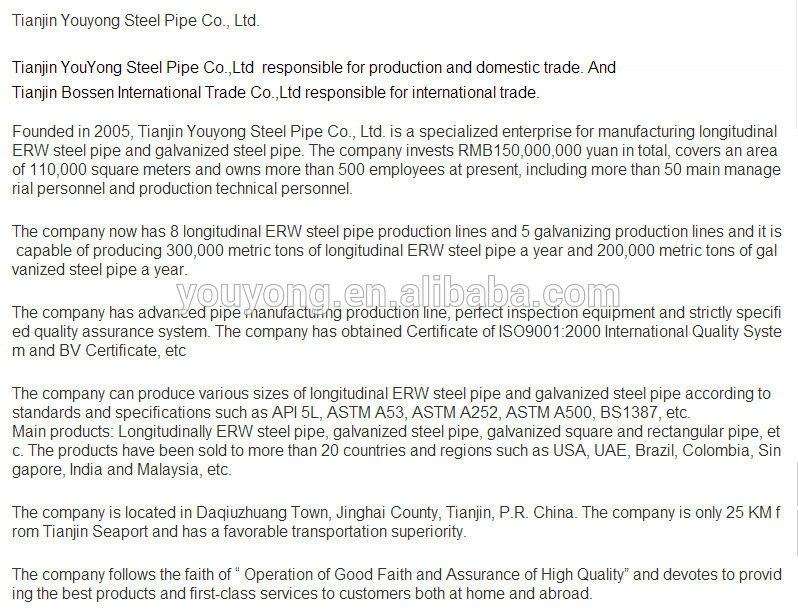

Briefing

Detailed

48.3mm Galvanized Steel Scaffolding Pipes are designed for pipes&coupler scaffolding.The pipes have hot-dipped galvanized surfaces finish so as to provide excellent appearance with sufficient durability in such applications where salty air or long-term weather exposures are inevitable.

Standard Size

| galvanized scaffolding pipeOutside diameter (mm) | galvanized scaffolding pipeWall thickness (mm) | galvanized scaffolding pipeLength (m) |

|---|---|---|

| 48.3-48.6 | 2.0-2.5 | 0.3-12 |

| 48.3-48.6 | 2.75 | 0.3-12 |

| 48.3-48.6 | 3.0 | 0.3-12 |

| 48.3-48.6 | 3.25 | 0.3-12 |

| 48.3-48.6 | 3.5 | 0.3-12 |

| 48.3-48.6 | 3.75 | 0.3-12 |

| 48.3-48.6 | 4.0 | 0.3-12 |

1. TOLERANCE:

a) On Specified OD + 0.5mm (Ovality 0.5mm)b) The Inside Diameter of ubes shall allow insertion of a guage of 37.7mm dia for a minimum length of 200mm.c) On Wall thickness -10%d) The mass deviation on a single tube shall not exceed -7.5% of the specified mass.

2. ENDS:

Cut cleanly and nominally square with the axis of the tube and free from excessive burrs.

3. PROPERTIES:

a) Chemical (Maximum) C - 0.20%, SI - 0.05%, MN - 1.40%, P - 0.04%, S - 0.045%, AL - Min. 0.02%.b) Mechanical = UTS - 340 to 520 N/mm2, YS - 235 N/mm2 (minimum) & %Elongation on 5.65 S0 - 24% (minimum).

4. FLATTENING TEST WELD AT 90 DEGREES (COLD):

a) For weld : Distance between the platens, measured under load is not greater than 75% of the OD of tube.b) For Material :Distance Between the platens, measured under load is not greater than 60% of the OD of tube.

5. STRAIGHTNESS:

1 in 500 (In 1 meter it should not exceed 3mm).

6. ZINC COATING:

Minimum local coating thickness on the outside surface 40 microns.(GALVANIZING)

7. MARKING:

a) We can emboss mill sign "EN 39 UTP 3 or 4." online at every one meter interval over the length of pipe.b) We can do online stencilling as per customer needs.

8. PACKING:

Hexagonal type.

9. MILL TEST CERTIFICATE:

We can issue a MTC, certifying that the tubes supplied comply with this Standard.

You need a product

You May Like

- Nearest port for product export

- Xingang Port, Tianjin, China

- Delivery clauses under the trade mode

- FOB, CFR, CIF, CIP, DDP

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow