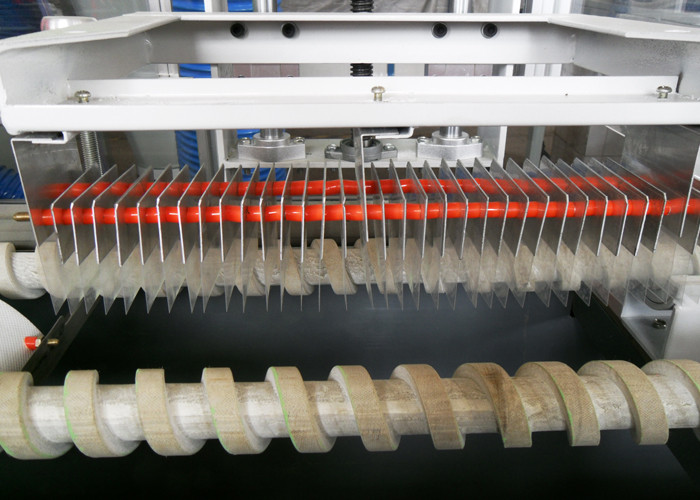

ND-JF90 Powder Coating Machine

group nameArmature powder coating machine

-

Min Order1 piece

brand nameNIDE

modelND-JF90GG

payment methodL/C, T/T

-

update timeTue, 19 Jul 2016 14:40:45 GMT

Packging & Delivery

Min Order1 piece

Briefing

Detailed

widely used armature insulating coating, such as the armatures for automotive, motorcycle, power cycle, toy, etc

1. Process flow

1). Assemble the fixture to the armature manually and put it on driving screw(below 2-6 items

complete automatically)

2).High frequency de-oiling

3).Intensive cooling

4).Electrostatic coating

5).Clamping apparatus cleaning

6).Powder high frequency heating and curing

7).Strong wind cooling(a little cooling)

8). Take out the finished part.

9).Disassemble the fixture manually and fixture come back to start working position by

convey.

2.The main configuration of the system

1).JF-90GG Electrostatic powder coating machine 1 unit

Machine size: L7500×W810(machine rack 750)×H-1350MM.

2).Equipment content structure Configuration

This machine is consist of pre-de-oiling, cooling, powder coating, Powder curing , cooling and powder recycling system

A. Pre-de-oiling

a).Adopt the advanced small-sized transistor high-frequency heating de-oiling, this machine

features fast heating speed, low energy-consumption and security etc.

b).Adopt small-sized fan with big blow volume, using this high-cool method it can cool the work

piece in short time

c).All the heating process are completed under the protection cover which made of organic

glass and new type aluminium section.

d).The heating area and cooling area has air pipe to exhaust, and the de-oiling heating area

has axial flow fan to extract the smog.

B. Powder Coating

a).Big power electrostatic high pressure device generates high-pressure stable and reliable

electrostatic, increasing the electrostatic adsorb power ability, and adhere sufficient powder

fast.

b).Coating fluidization box and powder feeding fluidization box can be disassembled quickly.

it's convenient to clean powder entirely. The fluidization box is installed with powder

activation vibration device. Even the powder in poor flow state, it could be full fluidized and

ensure uniformity of coated powder.

c).It's convenient and fast to load powder without overflow.

d).The powder in workpiece surface is very clean after cleaning process ,the powder in

the fixture is also very clean after though many powder-blow devices, without any effect to the

requested coating position.

e).High Post control pane with emergency stop is easy and convenient to manage. If any

emergency,it can stop all the work immediately(except the high-frequency pump, filament, low

voltage)

f).concentrating the electrical control position,easy to do maintenance and repair conveniently.

g).Adopt frequency conversion controller, constant speed, stable, steppless adjustment,

specific speed and workpiece output would be according to the status of powder curing.

h).It has automatic powder feeding device which can automatically feed powder continuously

and keep the volume of powder in the same level, thus to ensure the powder uniformity on the

workpiece.

i).The workpiece platform is installed in transparent dust cover(made of new type aluminium,

the appearance is agreeable, while the structure is solid), doors are available in the critical position to make operator easy. The air cooling device is installed behind the mainframe, integrated with the

mainframe.

j).The convey belt deliver the dissemble fixture back to feeding area, reducing the times for

operator going forward and backward, therefore, greatly increasing the productivity and

reducing the labor cost.

k).This system is with reliable performance, optimized structure.

C. Powder heating and curing.

a).The system adopts high-frequency(electron tube)induction heating, it can heat the

workpiece and melt powder quickly, and the heating depth is fleet, this is very helpful to melt

the powder which stick to the workpiece surface.

b).This system equips high-frequency cooling water box,the water tank equips independent

water cooling device.

D. powder recycling

The powder recycling system uses one set new type impulse filter element two-step powder

recycling device. The first step is using impulse backflushing to clean the powder in the filter

automatically. And the big blast volume of recycling can prevent the powder overflow to ensure

the environment protection.

Powder coating working station

You need a product

You May Like

- Nearest port for product export

- SHANGHAI, NINGBO

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C

- Export mode

- Have the independent export and import right