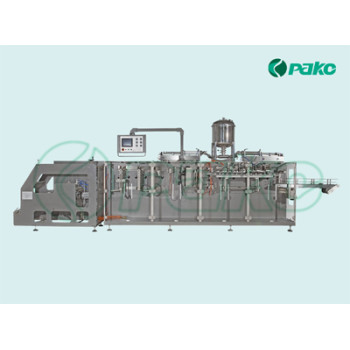

Horizontal Automatic Liquid Doypack Pouch Packing Machine

group namePouch Packing Machine

-

Min Order1 piece

modelDS-180S/DS-180SZ/DS-180SC

-

update timeSun, 15 Jul 2012 19:30:19 GMT

Paramtents

Material Carbon Steel

Packging & Delivery

Min Order1 piece

Briefing

Detailed

Independent Film Unwind Unit: Ensure good control of film tensile force; More flexible for film roll width or pouch specification; Better doypack forming.

Servo Advance System: Easy computerized specification change; Stable pouch advance with less deviation; Big torquemoment of pouch.

Zipper Function: Independent zipper unwind device; Stable zipper tensile force control; Even zipper seal.

Spout Function: Even spout seal with good appearance; High spout seal strength, no leakage.

Packing Process: 1. Film Unwind; 2. Bottom Hole Punching; 3. Bag Forming; 4. Film Guide; 5. Bottom Seal; 6. Vertical Seal I; 7. Vertical Seal II; 8. Photocell; 9. Servo Advance; 10. Cutting Pouch Catching I; 11. Pouch Catching II; 12. Slant Opening Cutting; 13. First Pouch Opening Vibrator; 14. Spout Inserting; 15. Spout Seal; 16. Second Pouch Opening; 17. Air Flushing; 18. Filling I; 19. Filling II; 20. Auxiliary Pouch Stretching; 21. Heat Top Seal; 22. Cooling Top Seal; 23. Finished Product; 24. Outlet.

Model | DS-180S | DS-180SZ | DS-180SC |

Pouch Size | 90mm×110mm (Min.) | 90mm×110mm (Min.) | 90mm×110mm (Min.) |

180mm×250mm (Max.) | 180mm×250mm (Max.) | 180mm×250mm (Max.) | |

Filling Capacity | 1000ml | 1000ml | 1000ml |

Packaging Capacity | 40-70ppm | 40-70ppm | 40-70ppm |

Power | 8kw | 9kw | 9kw |

Air Consumption | 300NL/min | 300NL/min | 300NL/min |

Machine Dimensions | 6000L×1100W×1500H (mm) | 6000L×1100W×1500H (mm) | 6000L×1100W×1500H (mm) |

Weight | 2000kg | 2100kg | 2100kg |

Function | Doy Pack, Shape, Hanging Hole | Doy Pack, Shape, Hanging Hole, Zipper | Doy Pack, Shape, Hanging Hole, Spout |