Rotary BOP

group nameDrilling Rig Accessories

-

Min Order1 piece

modelall types

-

update timeMon, 08 Apr 2013 00:01:18 GMT

Paramtents

standard API 16A

Usage Oil Well

Type BOP

Condition New

Packging & Delivery

Min Order1 piece

Briefing

standard: API 16A

adopts doubleor single packing unit

The rotary dynamic sealing part adopts quic

Detailed

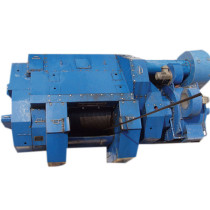

Rotary BOP

standard: API 16A

adopts doubleor single packing unit

The rotary dynamic sealing part adopts quick stripper cases

Rotary BOP

13 5/8” – 1500psi/3000psi rotary BOP is a type of well control equipment used in underbalanced drilling.

The major parts include: shell, locking assembly, rotary assembly and drill pipe actuator assembly. They fall into two types: BOPs with single packing unit and double packing unit respectively.

Structural characters

It adopts double packing unit or single packing unit

The rotary dynamic sealing part adopts quick stripper cases

Bearing are lubricated by force.

The cooling system realizes circular cooling to the upper dynamic parts

It adopts modular designs

specification

maximum static seal pressure 21Mpa(3000psi)

maximum dynamic seal pressure 10.5Mpa(1500psi)

maximum rotational speed 120rpm

base pipe bore size φ179.4mm(7 1/16”)

outer diameter of rotary assemble φ456mm(17 19/20”)

maximum seal size 5 1/4”hexagonal drilling pipe+ 5” drill pipe(with 18°/35°joint)

work medium drilling fluid, crude oil, natural gas

temperature rating for metallic material To(-18°~121°)

bottom connection 13 5/8”-5000psi 6B BX160flanged

side outlet connection 7 1/16”-5000psi 6B R46 flanged

21/16”-5000psi 6B R24flanged

Lubrication system maximum working pressure 16Mpa(2300psi)

Locking system rated working pressure 4Mpa(580psi)

Cooling circulation system working pressure 0.8Mpa(110psi)

Power 380V/50HZ

Note : all BOPs are designed and manufactured in accordance with SY/T6730. The resistance to stress corrosion by Hydrogen Sulphide at BOP positions in contact with fluide in the well meets relevant requirements as specified in NACE MR-0175.