HOT!!! API Oilfield Coiled tubing BOP

group nameSolids Control System

-

Min Order1 piece

modelFPH6.5-7.0, FPH6.5-35

-

update timeMon, 08 Apr 2013 00:36:15 GMT

Paramtents

Processing Type Forging

certification API

After-sales Service Provided Engineers available to service machinery overseas

application oilfield solid control

Warranty free for one year

Operation simple and easy

Packging & Delivery

Min Order1 piece

Briefing

CE/ISO certificate.

Top quality and best price.

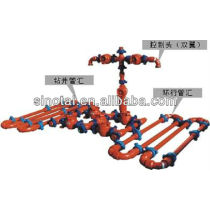

Coiled tubing BOP

Detailed

Meet API Spec 8A/8C standard

CE/ISO certificate.

Top quality and best price.

Coiled tubing BOP

Coiled tubing BOP

Coiled tubing BOP is a key part in well logging devices, and it is mainly used to control pressure at the wellhead during the process of well logging, well workover and production test, so as to effectively avoid blowout and to realize safe production.

A coiled tubing BOP is composed of quad ram BOP and stripper assembly.

1.When the tubing exists in the well, with the help of packing of certain size,the BOP can close the circular space

between the bore and pipe string and prevent the fluid in the well from overflowing.

2.When there is no string in the well, the BOP can completely close the well head with blind ram.

3.When in emergency, the tubing in the well goes up or down, a slip ram may be used to lock the tubing

to avoid any accident.

4.When the well is closed, with the help of kill manifolds and choke manifolds connected to the spool and side outlet on the body, the BOP can realize some special operation such as throttling and relief.

Model | 2 9/16”-10000psi 4 Quad Ram BOP 4FZ6.5-70 | 2 9/16”-5000psi Quad Ram BOP 2FZ6.5-35 | ||

Bore size | 65mm( 2 9/16”) | |||

Rated working pressure | 70Mpa(10000psi) | 35Mpa(5000psi) | ||

Hydrostatic shell test pressure | 105Mpa( 15000psi) | 52.5Mpa(7500pai) | ||

Operating chamber rated working pressure | 21Mpa(3000psi) | |||

Hydrostatic operating chamber working pressure | 31.5Mpa(4500psi) | |||

Recommended operating chamber working pressure | 8.4~10.5Mpa (1200~1500psi) | |||

Volume to open( per set) | 1.5L(0.40gal) | 1L(0.26gal) | ||

Volume to close(per set) | 1.5L(0.40gal) | 1L(0.26gal) | ||

Hydraulic connection parts | M22 X1.5 or as required by contract | |||

Body side outlet | 2 1/16” – 10000psi | 2 1/16”-5000psi | ||

Temperature rating | T20(-29~121°C) | |||

Closing ratio | 1:8.92 | 1:6.56 | ||

Specification of rams available | C.S.O, SBR, 1”, 1 1/4”, 1 1/2”, 1 3/4”, 1”slip ram, 1 1/4” slip ram | |||

Top connection | 2 9/16”-10000psi studding connection | 6.312-4-ACME union connection | 4.75-4-ACME union-male | |

Bottom connection | 2 9/16”-10000psi flange connection | 2 9/16”-10000psi flange connection | 4.75-4-ACME union-fale | |

Overall dimension height(H) | 930mm(36.61”) | 950mm(37.40”) | 550mm(21.65”) | |

Approx weight | 1020kg(2249lb) | 1107kg(2441lb) | 956kg(2108lb) | |

Stripper assembly can be used to perform the following operation

1.When there is tubing in the well, with the help of packing of certain size, the BOP can close the annular space between the bore and tubing and prevent the liquid in the well from kicking.

2.When the tubing in the well moves up or down, turning the pressure at the stripper control oil line can protect the surface of liquid lubrication in the well and to prevent the liquid in the well from the kicking.

Model | 2 9/16”-10000psi BOP FPH6.5-7.0 | 2 9/16”-5000psi BOP FPH6.5-35 | |

Bore size | 65mm( 2 9/16”) | ||

Rated working pressure | 70Mpa(10000psi) | 35Mpa(5000psi) | |

Hydrostatic shell test pressure | 105Mpa( 15000psi) | 52.5Mpa(7500pai) | |

Maximum pressure for packing hydraulic control system | 21Mpa(3000psi) | ||

Intensive pressure for packing hydraulic control system | 31.5Mpa(4500psi) | ||

Maximum pressure for round window hydraulic control system | 10Mpa (1450psi) | ||

Intensive pressure for round window hydraulic control system | 31.5Mpa(4500psi) | ||

Volume to open( per set) | 0.7L(0.18gal) | 0.7L(0.18gal) | |

Volume to close(per set) | 2L(0.53gal) | 0.7L(0.18gal) | |

Hydraulic connection parts | M12 X1.5 or as required by contract | ||

Temperature rating | T20(-29~121°C) | ||

Specification of matching packing | 1”, 1 1/4”, 1 1/2”packing | ||

Top connection | 4.75-4-ACME union-male | 4.75-4-ACME union-female | |

Bottom connection | 2 9/16”-10000psi flange connection | 4.75-4-ACME union-female | |

Overall dimension height(H) | 1190mm(46.85”) | 892mm(35.12”) | |

Approx weight | 235kg(518lb) | 182kg(401lb) | |