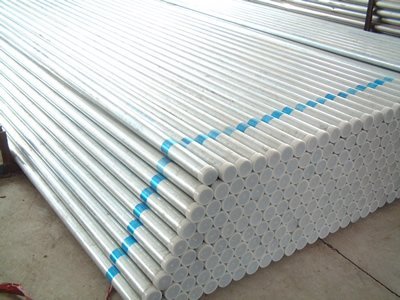

HDG Steel Pipe(ASTM A53,EN39)

group nameHot dip galvanized round steel pipe(tube)

-

Min Order18 piece

brand nameTYTSTEEL

payment methodT/T, L/C, D/P D/A, MoneyGram, Credit Card, Westem Union, Escrow

-

update timeFri, 01 Mar 2013 10:25:21 GMT

Paramtents

Technique ERW

Grade ST35-ST52, Q195-Q345

Thickness 1.4 - 8.75 mm

Zinc coating content 280 g/m2

Outer Diameter 21.3 - 219.1 mm

Application Electrical,Fluid,construction scaffolding and conduct pipe

Packging & Delivery

Min Order18 piece

Briefing

Size: 1/2"-8"

Thickness:1.4-8.75mm

Length:3-12meter

Standard: ASTM A53,BS

Detailed

HDG Steel Pipe(ASTM A53,EN39)

Size: 1/2"-8"

Thickness:1.4-8.75mm

Length:3-12meter

Standard: ASTM A53,BS1387,EN39

HDG Steel Pipe(ASTM A53,EN39)

DIAMETER:DN15-DN200

WT:1.4-8.75mm

Length: 3 to 12 m

Grade:Q195 Q215 Q235 ST37 ST52

Delivery status:Hot dipped galvanized

Zinc coating: 280g/m2

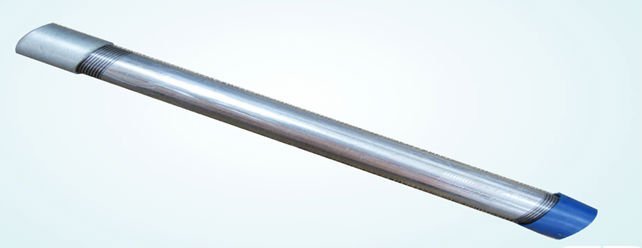

Ends:Screwed both ends and complete with one solid coupling(socket)

Usage: Electrical,water transportation and conduct pipe

LIFE : More than 10 years

Reference Standard En39:

Type |

|

| Outside Dia. of Black /Galvanized Tube |

|

| Weight of Black/ Galvanized Tube | |||||

| Size | Minimum | Maximum | Wall thickness | Plain ends | Pieces | |||||

| NB(mm) | inches | mm | inches | mm | inches | mm | inches | Kg/ft | Kg/meter | Per bundle |

3 | 40 | 11/2 | 47.8 | 1.882 | 48.8 | 1.921 | 3.2 | 0.126 | 1.090 | 3.56 | 61 |

4 | 40 | 11/2 | 47.8 | 1.882 | 48.8 | 1.921 | 4.0 | 0.157 | 1.332 | 4.37 | 50 |

1. TOLERANCE

:a) On Specified OD + 0.5mm (Ovality 0.5mm)

:b) The Inside Diameter of tubes shall allow insertion of a guage of 37.7mm dia for a minimum length of 200mm.

:c) On Wall thickness -10%

:d) The mass deviation on a single tube shall not exceed -7.5% of the specified mass.

2. ENDS

: Cut cleanly and nominally square with the axis of the tube and free from excessive burrs.

3. PROPERTIES

:a) Chemical (Maximum) C - 0.20%, SI - 0.05%, MN - 1.40%, P - 0.04%, S - 0.045%, AL - Min. 0.02%.

:b) Mechanical = UTS - 340 to 520 N/mm2, YS - 235 N/mm2 (minimum) & %Elongation on 5.65 S0 - 24% (minimum).

4. FLATTENING TEST WELD AT 90 DEGREES (COLD)

a) For weld : Distance between the platens, measured under load is not greater than 75% of the OD of tube.

b) For Material :Distance Between the platens, measured under load is not greater than 60% of the OD of tube.

5. STRAIGHTNESS

: 1 in 500 (In 1 meter it should not exceed 3mm).

6. ZINC COATING

: Minimum local coating thickness on the outside surface 40 microns.

(GALVANIZING)

7. MARKING

: a) We can emboss mill sign "EN 39 UTP 3 or 4." online at every one meter interval over the length of pipe.

b) We can do online stencilling as per customer needs.

8. PACKING

: Hexagonal type.

9. MILL TEST CERTIFICATE

:We can issue a MTC, certifying that the tubes supplied comply with this Standard.

You need a product

Related Searches

You May Like

- Nearest port for product export

- TIANJIN XINGANG PORT, QINGDAO PORT, SHANGHAI PORT, NINGBO PORT

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, CIP, CPT, DDP, DDU

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, Westem Union, Escrow