HD242 Gas Boiler Parts

group nameIndustrial infrared burners

-

Min Order100 piece

brand nameHAODONG

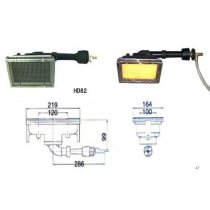

modelHD242

-

update timeFri, 15 Mar 2013 15:39:35 GMT

Paramtents

Type Gas Burner

Packging & Delivery

Min Order100 piece

Briefing

2.Environmental friendly

3.High-efficiency

4.Life:11000hr

5.Used for g

Detailed

1.Energy saving Gas Boiler Parts

2.Environmental friendly

3.High-efficiency

4.Life:11000hr

5.Used for gas oven,stove

HD242 Gas Boiler Parts:

Model | Length (mm) | Width (mm) | Height(mm) | Weight (kg) | Consumption | Heat Output | Inlet Port (Inch) | ||

NG | LPG | ||||||||

m3/h | kg/h | KW/h | Kcal/h | 3/8 | |||||

HD242 | 840 | 130 | 175 | 11.7 | 0.74 | 0.68 | 9.4 | 8120 | |

Gas Boiler Parts features:

1. Energy saving:conversion rate:≥90%

2. Environmental protection:CO≤80ppm;NOx≤10ppm;CHx≤50ppm

3.Taking full usage of heat:95% of energy released in the form of infrared ray ;heating the objects directly

4. Long life:≥11000hr

5. Easily installed

6. Main market: Asia, Europe, America, Mideast

Applied Range

Food Industry: Rice Biscuit( rice cookies covered with snow-like sugar )assembly line, grilled chicken, biscuit, egg roll, roasting shredded squid oven, oven for roast duck, smokeless oven, griddle, middle eastern oven, hot pot oven, roasting pachyrhizus oven, snack car, soup oven, cooking assembly line, infra-red gas baking pan, deep-fry assembly line, water-removing machine, baking, etc.

Painting Industry: Liquefied or powered painting assembly line, warm-up, preliminary treatment of heating, desiccating wood, galvanization drying assembly line, phosphatization drying assembly line

Fiber industry: Carpet latex dryer, dyeing dryer, printing dryer, textile dryer, industrial clothes dryer, latex gloves drying assembly line

Glass and ceramics industry: Enamel firing dryer, glass oven, heat-setting machine, mould drying, fritting, parching

Paper industry: All kinds of paper dry lines and auxiliary drying heat wall

Farming and animal husbandry: Heating of barton, heating of crops, grain dryer

Summary:

- Infrared catalytic burner uses the porous cordierite honeycomb combustion plate with a special catalyst coated as a core component .

- Its catalytic combustion is the best combustion mode ,which means that gas (natural gas, liquefied petroleum gas) and combustion-supporting gas (air) are mixed according to the scientific proportion through burner shell (pre-mixed room) with the precise design and manufacturing .

- Ignited by the ignition, the gas mixture is burning on surface of catalyst which lies in the holes of porous cordierite honeycomb plate .

- The vast majority(95%) of the heat generated in the form of infrared radiation penetrate the object directly,put an end to energy loss caused by heating the air to heat the object, the mode of heat convection heating , greatly improve the energy conversion ability so as to further save the energy (save 60% of the operation costs under the same industrial conditions compared to the ordinary heating mode --electric heating ).

- Gas is almost under complete combustion as a result of catalytic combustio. the flue gas pollution is extremely low (CO <0.02%, NO x <10ppm) ,fully meeting the national environmental standards and there is no need for direct exhaust fan.

Technical data

Items | Technical parameters |

Types |

natural gas (NG),liquefied petroleum gas (LPG) |

Light-off temperature | ≥350 |

complete combustion temperature | ≤380 |

Heat source temperature | around 850 |

Baking temperature range | 30---850 |

Wavelength range | 1.9μm--15μm |

Furnace pressure natural | 2000pa(NG)/2800pa(LPG) |