Energy-saving Infrared Industrial lpg Burner HD162

group nameIndustrial infrared burners

-

Min Order50 piece

brand nameHAODONG

modelHD162

-

update timeFri, 15 Mar 2013 15:40:09 GMT

Paramtents

Technology rare-earth catalytic combustion

Fuel NG,LPG

Radiant parts cordierite honeycomb with catalyst-coated

Working pressure LPG 2800pa-5000pa

Type Gas Burner,infrared catalytic Industrial lpg Burner

Nozzle brass

Packging & Delivery

Min Order50 piece

Briefing

2.Energy-saving

3.Eco-friendly

4.High radiation efficiency

5.Low cost of acc

Detailed

1.IR industiral lpg burner

2.Energy-saving

3.Eco-friendly

4.High radiation efficiency

5.Low cost of accessories equipment

Energy-saving Infrared Industrial lpg Burner HD162

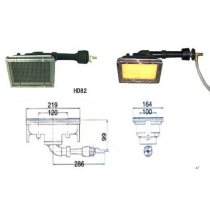

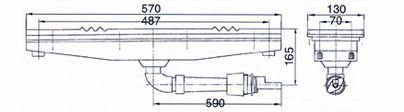

Model | Length (mm) | Width (mm) | Hight(mm) | Weight (kg) | Consumption | Heat Output | Inlet Port (Inch) | ||

NG | LPG | ||||||||

m3/h | kg/h | KW/h | Kcal/h | 3/8 | |||||

HD162 | 570 | 130 | 175 | 8.0 | 0.49 | 0.45 | 6.3 | 5400 | |

As we know, usually, there are three ways to transfer heat, Radiation, Convection, Conduction and their thermal efficiency decrease in turn.Most Equipment is mainly by convection to heat air first and then, the heated air transfer to object. Heat loss is big.But, differently, infrared burner heat object directly by radiation and transfer rate will be much higher.

Comperated with other industrial LPG burner,Catalytic infrared LPG burner have follow advantages:

1.High energy transfer rate, usually the transfer rate can reach 95%,but common gas burner only 75%~80%.

2.High efficiency. Infrared burner will be in working condition for 8seconds.And installed with quantity as 3.design, it can reach target temperature in ~10mins for empty oven and 25~40min when with cured objects in oven.

4.Single operation, one among them damage will not affect other's work, but if there’s any small problem with the gas burner, the curing will be stopped.

5.Heating directly, infrared burner heat object directly through radiation, not need other auxiliary equipment,like combustion chamber, blower….

6.Low cost of equipment, martch with our accessories,only need a temperature controller and pressure instrument,connect them with gas pipes and wires, them it will work.

Types Parameters | Electric Stove | Oil Burner | Coal-fired Furnace | Infrared Catalytic Burner |

Heat Energy Requirement | 10000 Kcal | 10000 Kcal | 10000 Kcal | 10000 Kcal |

Set Point of Temperature | 180°C | 180°C | 180°C | 180°C |

Consumed Energy | 15Kw-hr | 2kg diesel fuel+1kw-hr | 10kg coal | 0.9kg LPG |

Price of the Consumed Energy | 12/ $1.76 | 7/ $1.03 | 2.3/ $0.34 | 0.7/ $0.39 |

Heating-up Time | 20mins | 40mins | 90mins | 5-8mins |

Application:

Infrared catalytic gas burner is good choice industrial drying,baking or curing oven,especially in tunnel&converyor oven,saving production&equirpment cost,demand of space is small and easy to control......It martched with auto-igntion,safe controller and keep stable temperature.Now is already widely used industrial drying,especially in metal curing & food baking.......

a) Food Baking oven:

Rice Biscuit( rice cookies covered with snow-like sugar )assembly line, grilled chicken, biscuit, egg roll, roasting shredded squid oven, oven for roast duck, smokeless oven, griddle, middle eastern oven, hot pot oven, roasting pachyrhizus oven, snack car, soup oven, cooking assembly line, infra-red gas baking pan, deep-fry assembly line, water-removing machine, baking, etc. Usually the baking heating temperature range is 260 centigrade.

b) Painting Industry:

Liquefied or powered painting assembly line, warm-up and preliminary treatment of heating, desiccating wood, galvanization drying assembly line, phosphatization drying assembly line and so on. Different kinds of material need setting different temperature.

c) Fiber industry:

Carpet latex dryer, dyeing dryer, printing dryer, textile dryer, industrial clothes dryer, latex and medical gloves drying assembly line

d) Glass and ceramics industry:

Enamel firing dryer, glass oven, heat-setting machine, mould drying, fritting and parching. Glass product annealing process temperature is usually 500 centigrade.

e) Latex Products & Paper industry:

All kinds of paper and Latex products dry lines and auxiliary drying heat wall, often needs 180 centigrade.

f) Farming and animal husbandry:

Heating of crops, grain, vegetable, fruit, chicken farm warming, animal room heating etc.

g) Dehydration industry:

Various vegetables and fruits dehydration process, usually setting the oven temperature is 180 centigrade.

Application photo 1: Color steel plate curing oven outside.

Gas storage:

Usually,for a basic LPG gas storage,it need a pressure regulator and a manual valve for each cylinder, a pressure gage at the manager pipe. They can keep the pressure in the burner working rang: 2800pa~5000pa.

For more information,welcome to contact us--Haodong Technology,Believe we can offer you what you want!!