New Type Infrared bread oven Burner HD61

group nameBaking oven burners

-

Min Order50 piece

brand nameHAODONG

modelHD61

-

update timeFri, 15 Mar 2013 15:48:14 GMT

Paramtents

Technology Rare-earth catlalytic combustion

up cover stamped metal

radiant parts ceramic plate with catalyst coated

Working pressure 2000~5000pa

Power Source Gas

nozzle brass

Packging & Delivery

Min Order50 piece

Briefing

2.Environmental friendly

3.High efficiency

4.Longlife: above 11000hr

5.Market:Asia,Eur

Detailed

1.Energy saving;

2.Environmental friendly

3.High efficiency

4.Longlife: above 11000hr

5.Market:Asia,Euro,Mideast,America

New Type Infrared bread oven Burner HD61

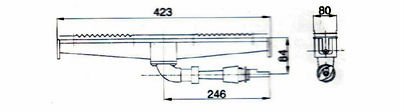

Model | Length (mm) | Width (mm) | Height(mm) | Weight (kg) | Consumption | Heat Output | Inlet Port (Inch) | ||

NG | LPG | ||||||||

m3/h | kg/h | KW/h | Kcal/h | 1/8 | |||||

HD61 | 423 | 80 | 94 | 3.8 | 0.18 | 0.17 | 2.4 | 2030 | |

Different from other infrared burner,Haodong IR burner is based on rare earth catalytic combustion technology,which is high effieciency and energy-saving. It make a whole combustion and save more than 10% energy than non-catalytic IR burner. At the same time,it can prolong the use life of ceramic plate.

We have three accessories for this burner,Electric pulse Igniter,Ignition Pin and Solenoid Valve.They are mainly used to realize auto-ignition,help to keep stable temperature and protect from gas leakage.

Infrared catalystic burner features:

Energy saving:conversion rate:≥90%

Environmental protection:CO≤80ppm;NOx≤10ppm;CHx≤50ppm

Taking full usage of heat:95% of energy released in the form of infrared ray ;heating the objects directly

Long life:≥11000hr

Easily installed

Main purposes:

Infrared catalytic gas burner is good choice industrial drying,baking or curing oven,especially in tunnel&converyor oven,saving production&equirpment cost,demand of space is small and easy to control......It martched with auto-igntion,safe controller and keep stable temperature.Now is already widely used industrial drying,especially in metal curing & food baking.......

1. Coating Industry: forging heat coating, liquid, powder coating, pre-heating the water to deal with dry acid.

2. The food industry: drying for processed food such as cookies, egg rolls, snow rice cakes, shredded squid, fish sauce, ham etc;tea processing and baking.

3. Agriculture and animal husbandry: keeping warm for a variety of birds, the livestock shed;grain drying.

4. Food and beverage industry: all kinds of barbecue, fruit and vegetable dehydration.

5. Drying operation in printing and dyeing, paper, wood, carpet and other industries

6. Bake ceramic mold industry, the Health and embryos, the surface drying of glazed ceramic tiles.

7. The heat treatment of metallic materials (300 --- 800 ).

8. Heating ,warming and insulation for commercial buildings and workshop

The user manual

Table 1:The use of technical parameters

Items

| Technical parameters |

Types |

natural gas (NG),liquefied petroleum gas (LPG)

|

Light-off temperature | ≤350 |

complete combustion temperature | ≤380 |

Heat source temperature

| around 850 |

Baking temperature range | 30---850 |

Wavelength range | 1.9m--15m |

Furnance pressure natural | gas 150mmAq;liquefied petroleum gas 280mmAq

|

Table 2:

Comparison table for all kinds of energy consumption

Furnace type

Parameters | Electronic cooker

| Oil furnace | Coal-fired furnace

| Infrared catalytic heaters |

Energy requirement

| 10,000Kcal | 10,000Kcal | 10,000Kcal | 10,000Kcal |

Temperature | 180 | 180 | 180 | 180 |

Energy consumption

| Electricity(15 kW/h)

| Electricity (1Kw/h)+ diesel (2Kg) | Coal (10Kg)

| LPG(0.9Kg) |

Heating time

|

20 minutes

| 40 minutes | 90 minutes | 5-8 minutes

|