Catalytic Burner HD220

group nameBBQ infrared burners

-

Min Order100 piece

brand nameHAODONG

modelHD220

-

update timeWed, 07 Aug 2013 12:44:32 GMT

Paramtents

Type Grills,Infrared gas burner

Grill Type Gas Stoves

Metal Type Iron

Finishing Chrome Plated

Feature Easily Assembled,Easily Cleaned,Electronic Pulse Ignition

Safety Device Flame Safety Device,High Pressure Protection Device,Oxygen Depletion Safety Device

Conversion rate above 90%

CO less than 80ppm

NOx less than 10ppm

CHx less than 50ppm

Life above 11000hr

Packging & Delivery

Min Order100 piece

Briefing

2.Low emissions (NOx,CO)

3.High-efficiency

4.Durable

5.Catalytic burner in gas for stove,oven

Detailed

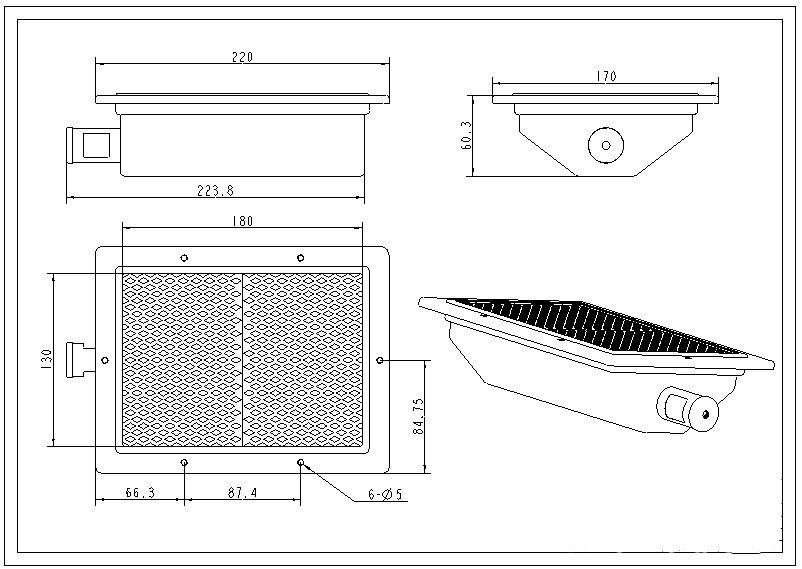

Catalytic Burner HD220 :

Model | Length (mm) | Width (mm) | Hight (mm) | Weight (kg) | Consumption | Heat Output | ||

NG | LPG | |||||||

m3/h | kg/h | BTU/h | KW/h | |||||

HD220 | 220 | 170 | 60 | 0.9 | 0.29 | 0.22 | 10000 | 2.94 |

Advantages of HD220 Catalytic Burner:

- Energy saving: more than 50% gas energy and cost can be saved than traditional burners; conversion rate≥90%

- Environmental friendly: CO≤80ppm;NOx≤10ppm;CHx≤50ppm

- Whole combustion: 95% of energy released in the form of infrared ray; heating the objects directly

- Long useful time: ≥11000hr

- Easily installed

- Main market: Asia,Euro,Mideast,Americas

Main Purpose of HD220 Catalytic Burner:

- Barbeque, food baking process and so on. It can save 50% energy when using this kind of products;

- mainly installed on the innermost firewall of ovens;

- The combustion front is at right angle to a plane. So it is usually called back furnace;

- It is widely used in high-grade combined-type oven in North America and in snack car/teppanyaki/duck furnace in China.

Product summary:

- Infrared catalytic burner uses the porous cordierite honeycomb combustion plate with a special catalyst coated as a core component .

- Its catalytic combustion is the best combustion mode ,which means that gas (natural gas, liquefied petroleum gas) and combustion-supporting gas (air) are mixed according to the scientific proportion through burner shell (pre-mixed room) with the precise design and manufacturing .

- Ignited by the ignition, the gas mixture is burning on surface of catalyst which lies in the holes of porous cordierite honeycomb plate .

- The vast majority(95%) of the heat generated in the form of infrared radiation penetrate the object directly,put an end to energy loss caused by heating the air to heat the object, the mode of heat convection heating , greatly improve the energy conversion ability so as to further save the energy (save 60% of the operation costs under the same industrial conditions compared to the ordinary heating mode --electric heating ).

- Gas is almost under complete combustion as a result of catalytic combustio. the flue gas pollution is extremely low (CO <0.02%, NO x <10ppm) ,fully meeting the national environmental standards and there is no need for direct exhaust fan.

Technical parameters

Items | Technical parameters |

Types | natural gas (NG),liquefied petroleum gas (LPG) |

Light-off temperature | ≥350°c |

complete combustion temperature | ≤380°c |

Heat source temperature | around 850°c |

Baking temperature range | 30---850°c |

Wavelength range | 1.9m--15m |

Furnance pressure natural | gas 150mmAq;liquefied petroleum gas 280mmAq

|

Comparison table for all kinds of energy consumption

Furnace type

Parameters | Electronic cooker

| Oil furnace | Coal-fired furnace

| Infrared catalytic heaters |

Energy requirement | 10,000Kcal | 10,000Kcal | 10,000Kcal | 10,000Kcal |

Temperature | 180 | 180 | 180 | 180 |

Energy consumption | Electricity(15 kW/h) | Electricity (1Kw/h)+ diesel (2Kg) | Coal (10Kg) | LPG(0.9Kg) |

Heating time | 20 minutes | 40 minutes | 90 minutes | 5-8 minutes |