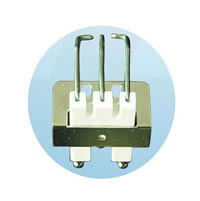

2013 Industrial coating curing oven burner(HD101)

- US $58.00

50 - 40,000 piece

- US $44.00

40,001 - 999,999 piece

group namePowder coating oven burners

-

Min Order50 piece

brand nameHAODONG

modelHD101

-

update timeWed, 07 Aug 2013 13:15:08 GMT

Paramtents

Condition New

Type Induction Furnace

Usage powder coating curing, drying oven, painting line

Voltage 110V/220V

Power(W) 3.9KW/h

Dimension(L*W*H) 690*80*115mm

Weight 7.4KG

life above 11000hrs

CO less than 80ppm

NOx less than 10ppm

CHx less than 50ppm

Tcehnology rare-earth catalytic combustion

Shell cast iron

Burner plate cordierite honeycomb with catalyst-coated

Color black

Fuel NG/LPG

Packging & Delivery

Min Order50 piece

Briefing

1.Energy-saving and Eco-friendly

2.Full combustion

3.Long life-span

Detailed

Energy-saving, high effieciency, flameless&smokeless!!

2013 Industrial coating curing Oven Burner(HD101)

About us

~~Haodong Technology now isthe first and onlycompany who applyrare-earth catalytic combustin technologyon infrared burner&heater.

Now we produce: food baking oven burner, infrared burner, gas heater, poultry heater, gas brooder, , industrial powder coating oven heater etc.

Parameters:

MODEL | Net Weight | Dimension | Consumption | Heat Output | ||

kg | mm | NG(m3/h) | LPG(kg/h) | KW/h | Kcal/hr | |

HD101 | 7.4 | 690*80*115 | 0.3 | 0.28 | 3.9 | 3380 |

Advantages:

1. Flameless and smokeless

2. Energy and Cost saving (can save 10%-20% energy than common burner)

3. Environmental protection(CO≤80ppm;NOx≤10ppm;CHx≤50ppm)

4. No need for a long and expensive preheating, it will reach comfort temperature very quickly.

5. Long useful time: ≥11000hr

6. High transfer capacity of heat energy: ≥95% energy can be released in the form of infrared ray

7. High efficiency: it can come to working condition in 8seconds.

8. Easyly installed in all direction

9. Naturally aspirated burner(no need of accessories equipment,like air blower,fire chamber... )

The most big advantages: Energy-saving and Flamsless!!

Comparison table for all kinds of energy consumption

Furnace type Parameters | Electronic | Oil furnace | Coal-fired furnace | Infrared catalytic burner |

Energy requirement | 10,000Kcal | 10, 000Kcal | 10, 000Kcal | 10, 000Kcal |

Temperature | 180 | 180 | 180 | 180 |

Energy consumption | Electricity(15 kW/h) | Electricity(1Kw/h)+ diesel (2Kg) | Coal (10Kg) | LPG(0.9Kg) |

Heating time | 20 minutes | 40minutes | 90 minutes | 5-8 minutes |

Applications:

Painting Industry: Liquefied or powered painting assembly line, preliminary treatment of heating, desiccating wood, galvanization drying assembly line, phosphatization drying assembly line

We also supply electric thermostat controller, solenvoid valve, ignition pin, pulse igniter.

Any question or need, just contact us freely.