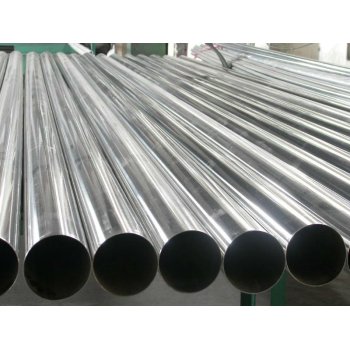

stainless steel tube

group nameUngrouped

-

Min Order10 piece

brand namezhaolida

payment methodT/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow

-

update timeThu, 24 Jan 2013 16:04:55 GMT

Paramtents

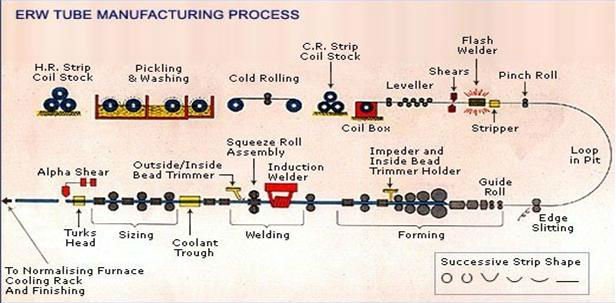

Technique ERW

Grade 10#-45#, Q195-Q345

Thickness 1.8 - 5.75 mm

Outer Diameter 19 - 500 mm

Application Fluid Pipe

Secondary Or Not Non-secondary

Packging & Delivery

Min Order10 piece

Briefing

1.Outer diameter:19-500mm

2Wall thickness:1.8-5.75

3Grade:Q195,Q235,Q345

4Stan

Detailed

stainless steel tube

1.Outer diameter:19-500mm

2Wall thickness:1.8-5.75

3Grade:Q195,Q235,Q345

4Standard:GB/T9711.1

stainless steel tube

1.Outer diameter:19-500mm

2Wall thickness:1.8-5.75

3Grade:Q195,Q235,Q345

4Standard:GB/T9711.1

stainless steel tube

National Standard | Enterprise Standard | Comparison Results | ||||

Welded Steel Pipe for Transportation of Low Pressure Fluid | Welded Pipe | |||||

Outside Diameter of Steel Pipe | Outside Diameter of Steel Pipe, Tolerance of Outside Diameter | Better than National Standards | ||||

Outside Diameter D/mm | Tolerance of Pipe Outside Diameter | Tolerance of Pipe End Outside Diameter/mm |

Outside Diameter D

|

8" |

±0.60mm | |

D≤48.3 | ±0.5mm |

| 5"-6" | ±0.50mm | ||

48.3<D≤168.3 | ±1.0% |

| 4" | ±0.40mm | ||

168.3<D≤508 | ±0.75% | +2.4 -0.8 | 3"-2½” | ±0.30mm | ||

D>508 | ±1.0% | +3.0 -0.8 | D≤2” | ±0.20mm | ||

Tolerance of Wall Thickness | ±12.5% | Wall Thickness S | 1.8-5.75mm | 5% | ||

Length

| Usual Length | Tolerance | Length |

|

| Better than National Standards |

D≤2” | +5-0 | |||||

4M-12M | +20-0 | 2½” ≤D≤4” | +10-5 | |||

Multiple length: 5-10mm tolerance for each Multiple length | +20-0 | 5” ≤D | +15-0 | |||

| +20-0 | |||||

Bending

| ≤168.3mm | Straight for ordinary use or negotiate the bending | Bending

|

| ≤1.5% | Better than National Standards |

>168.3mm | Smaller than 0.2% of full length of steel pipe |

|

| |||

Pipe End

| The two end faces of steel pipe should vertical with axes of the steel pipe. No burr in the incising | Pipe End | The two end faces of steel pipe should be vertical with axes of the steel pipe. No burr in the incising | Equal to International Standards | ||

≥168.3mm | Cutting tilt: no more than 5mm | ≥168.3mm | Cutting tilt: no more than 5mm | |||

Chemical Composition | Execute according to GB/T222, GB/T223 and GB/T4336 | Chemical Composition | Execute according to GB/T222, GB/T223, GB/T699, GB/T700, GB/T1591 and GB/T4336 | Better than International Standards | ||

Mechanical Properties | Execute according to GB/T228,GB/T6397, GB/T244 and GB/T246 | Mechanical Properties | Execute according to GB/T228, GB/T6397, GB/T244 and GB/T246 | Equal to International Standards | ||

Surface Quality Of Steel Pipe

| Internal and external surface of pipe should slick. Folding crack, delaminating and lap weld is not permitted. Other defects that no more than the negative deviance of wall thickness are permitted. Internal burr is allowed to exist. Steel pipe with>100mm, could be repaired for its defects and carry out water pressure experiment. |

Surface Quality Of Steel Pipe | Steel Pipe should not have defects such as crack, scar, folding, delimitation, and lap weld etc. Pull line, scoring, weld seam dislocation, scuffing not larger than the negative deviance of wall thickness and the trace of eliminating skin of ferric oxide and burr are allowed. Internal burr is allowed to exist. | Better than International Standards | ||

You need a product

You May Like

- Nearest port for product export

- xingang port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Westem Union, Cash, Escrow