Electronic compound potting sillicone rubber,liquid silicone rubber

- US $9.88

200 - 1,000 kilogram

group nameelectronic potting silicone rubber

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY9055

payment methodL/C, T/T, Western Union

-

update timeSat, 16 Nov 2013 09:02:31 GMT

Paramtents

application electronic potting compound silicone rubber

appearance liquid silicone

brand hongyejie

sample free

hs code 39100000

color any

supply ability 8 ton per day

payment L/C T/T

port shenzhen

ship by sea

Packging & Delivery

Size30cm x 40cm x 50cm

Weight25kg / kilogram

Min Order200 kilogram

Briefing

Detailed

Electronic compound potting sillicone rubber Application:

-high powered electronics,

-DC/DC module and circuit board which requires heat dissipation and high temperature resistance.

-It can be broadly used for LED screen, Wind Power Generator, PCB substrate, etc.

Electronic compound potting sillicone rubber Feature:

Electronic compound potting sillicone rubber for good elasticity is a kind of low viscosity, Inherent flame resistance, two components addtion cured potting silicone with heat-conducting. It cures with both on room temperature and heated temperature. It has the feature of the higher temperature the faster of the curing time. It can be applied to electronic components for insulation, waterproofing, fixed and flame retardant. It mainly applied in electronic components surface with materials of PC(Poly-carbonate),PP,ABS,PVC, etc. and metal materials.

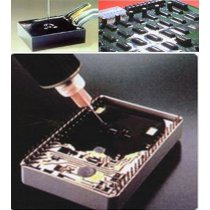

Electronic compound potting sillicone rubber Picture show:

Electronic compound potting sillicone rubber Datasheet:

Before Curing | Appearence | Black Fluid |

Density(25°C g/ml) | 0.98±0.02 | |

Viscosisty(25°Ccps) | Part A 2500±500;Part B:2500±500 | |

Mixing Ratio | A:B=1:1(By weight) | |

Operating Time(25°C min) | 120 | |

Curing time(25°C min) | 480 | |

Curing time(80°C min) | 20 | |

After Curing | Hardness(Shore A) | 50-60 |

Dielectric Strength(KV/mm) | 23 | |

Volume Resistance(Ω.Cm) | 1.0×10 15 | |

Permittivity(1.2MHz) | 3.0 | |

Temperature Resistence(°C) | -60~200 | |

Fire Resistance | UL94-V1 | |

Arc Resistance | 250V |

Electronic compound potting sillicone rubber technical guidelines:

1, Pls put part A and part B in separate container and stir evenly before mixing the two part together.

2, Mixing Ratio: part A: part B = 1:1

3, Deaeration the mixture in vacuum pump under 0.08 MPa for 3-5 minutes.Then the mixture could be used for pouring.

4, Pls note that the thickness of the silicone affects the curing time. If the silicone used is a little thick,then the curing time will be a little longer.The temperature also affects the curing time.When in lower temperature, we suggest customers appropriately heat the mixture to accelerate vulcanization. With temperature of 80~100°C, the silicone will cure in 15 minutes; while in 25°C room temperature, the silicone will cure around 8 hours.

Electronic compound potting sillicone rubber Notes:

1.The following material may hinder the curing of HY 9055, So pls use after the test. When necessary, pls clean the application areas.

Organotin compound or Condensation silicone with organotin

Sulphur, sulfide and sulfur rubber materials.

Amine compounds as well as contains the amine materials.

2. HY 9055 should be sealed storage.The mixture should be used up disposably to avoid causing waste.

3. HY 9055 belongs to non-dangerous goods, but keep away from mouth and eyes.

4. When it gets stratified after a period of storage, Please mix it evenly before using,which does not affect the performance.

Electronic compound potting sillicone rubber Package:

20Kg/pail as a set (Part A 10Kg + Part B 10Kg)

Electronic compound potting sillicone rubber Certification:

ISO9001: HK05/01358

SGS:GZ0606100461/CHEM

RoHS:BTRS091718751

Patent:ZL200520001597.8

About us:

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents