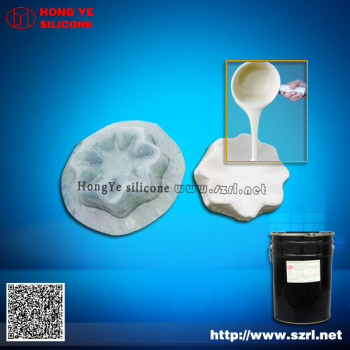

Casting silicone rubber (Tin catalyst silicone rubber series)

- US $10.00

100 - 40,000 kilogram

- US $7.00

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order100 kilogram

brand nameHong Ye silicone rubber

model638# 728# 788#

payment methodL/C, T/T, Western Union

-

update timeThu, 21 Nov 2013 08:37:25 GMT

Paramtents

color white/ off-white/ blue/ red

HS. Code 39100000

Appearance Liquid

Application Mold Making Silicone Rubber

Catalyst 4% free of charged

Molding method Pouring , brushing

Sample Free

MOQ 100KGS

Purity 100%

Packging & Delivery

Min Order100 kilogram

Briefing

Detailed

Casting silicone (Tin catalyst silicone rubber series) are generally named as two part room temperature sulfurated silicone rubber, which features an exceptional fluidity and good operability.When mixed with 2%-3% curing agent, they can still be operated within 30 minutes, but will be formed after 2-3 hours.With resistance to deformation, high temperature, acid and alkali, and expansion, silicon flexible molds are used for mold duplication and delicate mold making.

Datasheet of Casting silicone (Tin catalyst silicone rubber series)

Model: 625# Casting silicone (Tin catalyst silicone rubber series)

Appearance: white

Viscosity (cs): 22000

Hardness (A): 25

Tensile strength(kgf/cm2 ) ≥50

Tear strength (kgf /cm):≥35

Elongation break(%):≥6200

Retractility (%):≤0.2

Curing agent mixed rate (%):2-3

Operate time (min): 30

Curing time (hours): 2-4

Model: 728# Casting silicone (Tin catalyst silicone rubber series)

Appearance: white

Viscosity (cs): 24000

Hardness (A): 28

Tensile strength(kgf/cm2 ) ≥40

Tear strength (kgf /cm):≥25

Elongation break(%):≥500

Retractility (%):≤0.2

Curing agent mixed rate (%):2-3

Operate time (min): 30

Curing time (hours): 2-4

Features of Casting silicone (Tin catalyst silicone rubber series) :

(1) Silicon rubber with Reach and ROSH approval

(2) Curing agent arrange together as free charged

(3) In liquid form and in various colors

(4) With an exceptional fluidity and good operability.

(5)Temperature and deformation resistance as well as low shrinkage.

(6) High duplication times.

(7) Sample orders are available

(8) MOQ: 200KG

FAQs of Casting silicone (Tin catalyst silicone rubber series)

Eg:

Why is the appearance of the finished mold striate and unsmooth?

It is because the appearance of the product or the model itself is not perfect, and it has not been polished before the further operation. So when you make silicon molds, firstly you should polish the product, spray the mold spray evenly on the product. In this case, the problem can be avoided.

We are leading manufacturer in China for casting silicone, tin catalyst silicone rubber, liquid RTV-2 mold making silicone rubber in China, silicone,silicone rubber,mold making silicone,molding silicon,electronic silicone,RTV-2 silicon,RTV-2 silicone rubber, shoe mold rubber ,mold making silicone,RTV silicone rubber, artificial stone molding silicone, stone veneer molding silicone, casting silicone, plaster silicone, silicon for shoe soles silicone ,shoe soles silicone rubber,Lifecasting,shoe soles silicone, silicone products ,food grade silicone rubber etc.

More details of Casting silicone (Tin catalyst silicone rubber series) , pls feel free to contact Taylor:

Tel:086-755-89212380

Mob:086-18938867522

Skype: taylordl828

Facebook: hyw(at)szrl(dot)net

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents