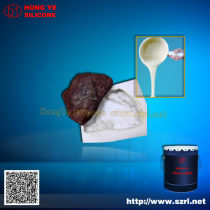

For stone molding silicone rubber

- US $9.58

200 - 40,000 kilogram

- US $6.88

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHy-630 silicone rubber

payment methodT/T, L/C, Westem Union

-

update timeTue, 05 Nov 2013 11:07:12 GMT

Paramtents

certificate ROHS,SGS,ISO9001:2000

Colour any color

Packging & Delivery

Min Order200 kilogram

Briefing

2.good operation

3.high tear and tensile strength

4.easy demould

Detailed

Liquid silicone rubber for stone mold making operations

Step One: Take 100g of part A and add 2g of part B and mix the Liquid silicone rubber for mold making and curing agent evenly.

tep Two: vacuum pumping

Note:Without exception, this step takes less than 10 minutes. Otherwise, The mixture of silicone rubber will cause , and no more further steps will be available.That`s a waste of liquid mould silicone rubber.

Step Three: Brushing cast & Perfusion Molding operation( further detail operation steps you want to know,pls do not hesitate to contact us!)

Liquid silicone rubber for stone mold making standard datasheet:

Model | Appearance | Viscosity (cs) | Hardness (A0) | Tensile Strength (kgf/c) | Tear Strength (kgf/) | Elongation (%) | Mixing ratio (%) | Operating Time(H) | Curing Time(H) |

630# | White | 15000~17000 | 26~28 | ≥35 | ≥22 | ≥470 | 2~3 | 0.5 | 2~4 |

FAQ of liquid silicone rubber for stone mold making

1.Why is the appearance of the finished mold striate and unsmooth?

t is because the appearance of the product or the model itself is not perfect, and it has not been polished before the further operation. So when you make silicon molds, firstly you should polish the product, spray the Liquid silicone rubber for mold making mold spray evenly on the product. In this case, the problem can be avoided.

2. Why does the silicone mold get burnt out?

This consequence happens only because you have left out the important notes when using unsaturated resin materials to produce your products. The unsaturated resin produces great heat when added the curing agent. So you must demould the product within 3 minutes to avoid this problem

Need any help on silicone rubber, please feel free to contact Ms Annie :

Tel: 0086-0755-89948294

Mob:0086-0755-18938861891

E-mail: hyjx(at)szrl(dot)net

skype: annie2012a

.

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents