Casting Liquid Silicon Rubber (Tin Catalyst Series)

- US $12.80

200 - 40,000 kilogram

- US $5.98

40,001 - 999,999 kilogram

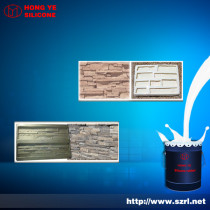

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY638# Casting Liquid Silicon Rubber (Tin Catalyst

payment methodT/T, L/C, Westem Union

-

update timeTue, 05 Nov 2013 11:23:58 GMT

Paramtents

color white

Certificate MSDS, SGS, RoHS . Reach, ISO

Application For molds making

Shape Pasty

Shelf Life 12 months

mixing ratio 100:4

packge vacumm pumping

delivery within 3 days after payment

payment terms T/T, L/C

transportation by sea, by air

Packging & Delivery

Min Order200 kilogram

Briefing

Low shrinkage

large reproduction times

Non deformation

light viscosity

Detailed

1.Casting Liquid Silicon Rubber (Tin Catalyst Series) applications:

Casting Liquid Silicon Rubber (Tin Catalyst Series) use in mold making field for toy gifts and craftwork gifts, poly technique, lightings, candles, and molds in multiple pieces.

2.Casting Liquid Silicon Rubber (Tin Catalyst Series) features:

Casting Liquid Silicon Rubber (Tin Catalyst Series) with the advantages of good tensile strength, high tear strength, high temperature resistance, high duplication times and repeated use, etc. It is suitable for small products or fine and precision products which is difficult to demould. This silicone rubber is one of the products with the highest use level in the production of craftwork gifts and the shrinkage is up to 0.3%.

3.Casting Liquid Silicon Rubber (Tin Catalyst Series) Using instruction:

Component A is white flowing liquid and component B is the curing agent. For example, take silicone rubber of 100g and add 2g curing agent for mixing evenly (silicone rubber and curing agent must be measured accurately). After the silicone rubber and the curing agent are completely mixed, put the silicon into a vacuum machine for deairing to remove the bubbles. After deaired, pouring the liquid silicone rubber into the product to be duplicated or into the mold frame. If you don't have vacuum machine, please add 1.2% or 1.5% curing agent so that the bubbles can bubble itself. Since the less curing agent you add, the slower the mould will curdle, the bubbles will bubble out itself.

4.More about Casting Liquid Silicon Rubber (Tin Catalyst Series), pls feel free to email or call Caroline

TEL: +86-755-89948019

Mobile: +86-18938867567

Skype: cathy19900719

Email: hysf(at)szrl(dot)net

Website : www(dot)szrl(dot)net

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents