RTV 2 silicone moulding rubber

- US $7.89

200 - 40,000 kilogram

- US $5.40

40,001 - 999,999 kilogram

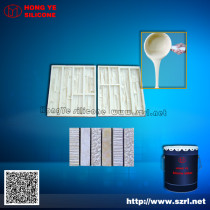

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelRTV-630,HY 630 silicone rubber

payment methodT/T, L/C, Westem Union

-

update timeTue, 05 Nov 2013 11:47:21 GMT

Paramtents

color white

certificate RoHS, MSDS, SGS, ISO9001:2000

Packging & Delivery

Min Order200 kilogram

Briefing

for flexible soap &candle molds making

for concrete &cement moulds making

Detailed

RTV 2 silicone mouldingrubber

application ofRTV 2 silicone mouldingrubber HY630

used for flexible soap &candle molds making ,concrete &cement moulds making and suitable for plaster or resin artwork molds making and so on .

Features of RTV 2 silicone mouldingrubber HY630

Low shrinkage, no deformation, good elasticity, high duplication times, etc.

RTV 2 silicone mouldingrubber HY630

Model | Color | Viscosity cps | Hardness (A°) | Tensile strength (Mpa) | Tear strength (KN/m) | Elongation % | Mixing ratio % | Pot life(H) | Demould time (H) |

630 | White | 24000-26000 | 30±2 | ≥≥4.1 | ≥2.9 | ≥420 | 2-3 | 0.5 | 2-4 |

Operations for RTV 2 silicone moulding rubber HY630:

Step One:Take 100g of part A and add 2g of part B and mix the silicon rubber and the curing agent evenly.

Step Two: vacuum pumping

Without exception, this takes less than 10 minutes. Otherwise, it will cause cross linking

reaction, and no more further steps will be available.

Step Three: Brushing cast & Perfusion Molding operation

Brushing cast:

a. Evenly brush the mixed silicon rubber on the product which is covered with mold spray with a brush or a brush pen.

b. After the cross linking reaction ( about 30 minutes ),brush a second coat which can increase the tension and tear

strength of the mold.

c. Cover a glass cloth on it after another 30 minutes of a second cross linking reaction, and use a brush pen or a brush to avoid any interstices.

d. Cover a third coat.(Note: if you have high requirements for the tension and the tear strength for the mold,please repeat step c and step d.Hence, the finished silicone moulds will have a good quality and a longer life, which can help you save cost and increase production efficiency.)

Perfusion Molding

The perfusion molding is an easy way to make molds, Slowly and evenly perfuse the mixed silicon rubber into the square frame. After the cross linking reaction.

Step Four: Operations for the external mold

a.Make a square frame with four pieces of wooden boards or rubber plates, then place the product which is covered

with the finished silicon rubber mould in the middle.

b.Slowly and evenly perfuse the gypsum to the square frame. Also you can brush the resin on the product which is covered with the finished silicon rubber mould with a brush or a brush pen. Repeat this process two or three time after the cross link reaction.

Any more information , pls feel free to contact Ms Shirley

office no. :0086-755-89948019

Mob:86-15220170905

Skype: patch8826

Email :hyh(at)szrl(dot)net

Welcome to our website www dot szrl dot net

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents