Platinum Silicones For PU Component Molds

- US $9.89

200 - 40,000 kilogram

- US $7.89

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelE642# silicone rubber

payment methodT/T, L/C, Westem Union

-

update timeTue, 05 Nov 2013 12:03:48 GMT

Paramtents

feature 1 light viscosity

feature 2 good tension

feature 3 low shrinkage

feature 4 good tension

Packging & Delivery

Min Order200 kilogram

Briefing

Detailed

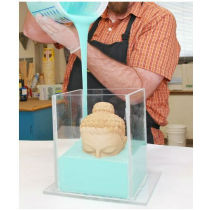

Platinum Silicones For PU Component Molds Performance:

Platinum Silicones For PU Component Molds,It has good electrical performance, chemical stability with features of waterproof, corrupt resistance, physiological inert, non-toxic, tasterlessness, aging-resistance, easy pouring, easy operation, and completely vulcanization. It can meet requirement of the Mechanical strength even under a very low hardness. When making printing pads, it will be with low shrinkage and can keep its initial hardness as original after a long time using. So it is the specially suitable material for life-casting and printing pad making.

Platinum Silicones For PU Component Molds Main applications

Platinum Silicones For PU Component Molds ,it is mainly used to make soft silicone products ,such as sex toys, body organs, body breast enhancers, shoulder pads, paster, trackion ,etc.

Platinum Silicones For PU Component Molds is a kind of nearly-colorless translucent fulid. We can adjust its color as per the request of customers.

Technical Datasheets of Platinum Silicones For PU Component Molds

Product | E-620 | E-630 |

E-640 |

Appearance | clear | clear | clear |

Hardness(shore A) | 20±2 | 30±2 | 40±2 |

Mix ratio(A:B) | 10:1 | 10:1 | 10:1 |

Viscocity Part A(cps) | 18000±2000 | 20000±2000 | 20000±2000 |

Viscocity Part B(cps) | 3000±500 | 5000±500 | 6000±500 |

Viscosity after mixing | 6000±1000 | 9000±1000 | 10000±2000 |

Tensile strength (kg/cm2) | 60±5 | 70±5 | 75±5 |

Tear-strength (kg/cm) | 24±2 | 22±2 | 22±2 |

Elongation(%) | 370 | 340 | 320 |

Densite | 1.03 | 1.09 | 1.12 |

Pot life/working time (mins) | 30-40 | 30-40 | 30-40 |

Curing time/setting time | 3-4hrs(25°C) 110-20mins(90°C) | 3-4hrs(25°C) 110-20mins(90°C) | 3-4hrs(25°C) 110-20mins(90°C) |

Shrinkage rate (%) | 0.1 | 0.1 | 0.1 |

Platinum Silicones For PU Component Molds Packaging, storage and transportation

1. This product need to be packed in clean, dry and sealed steel cans or drums. Part A and B need to be packed seperately. Usually it is packed in 5kg/can, 20 kg/drum, or 200 kg/drum .

2. Please keep the material in a cool and dry place. Specially note that the silicone should not touch or mix with compounds including nitrogen, phosphorus, sulfur, tin, lead or metal organic acid. Otherwise, the catalyst will be poisoned, then the silicone can not be cured or just particially cured. For specific precautions, please refer to the instructions in Electronic Potting Silicone part.

3. The goods is NOT subject to IMDG.The shelflife is 18 months from the date of production.And it still can be used after expired, when retest to be qualified.

Any information, please feel free to contact Ms. Judy

MOBILE:086-18938867591

SKYPE: judy.zhao723

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents