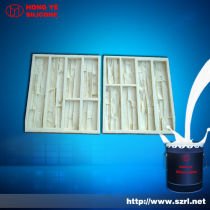

Mold Making Silicon Rubber, Mold Making Silicone Rubber

- US $9.38

200 - 40,000 kilogram

- US $6.98

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelhy630# silicone rubber

payment methodT/T, L/C, Westem Union

-

update timeTue, 05 Nov 2013 12:06:15 GMT

Paramtents

color white

Packging & Delivery

Min Order200 kilogram

Briefing

2.Good tensile and tear strength, low shrinkage.

Detailed

Mold Making Silicon Rubber, Mold Making Silicone Rubber

Mold Making Silicon Rubber, Mold Making Silicone Rubber Usage

Mold Making Silicon Rubber, Mold Making Silicone Rubber for PU/poly resin, unsaturated resin, plaster, candles and gypsums/concrete crafts, toys, artificial stone ,soap, statuary ,casting molds making,etc.

Model | 625# |

Appearance | white |

Mixing proportion of curing agent (%) | 4% |

Operating time (mins 25 0C ) | 30-45 |

Curing time(hours 25 0C) | 6-8 |

Hardness (A°) | 25 |

Density ( g/cm 3) | 1.08 |

Viscosity (mPas -25 0C) | 18000-20000 |

Tensile-strength(kgf /cm2) | ≥39 |

Tear-strength (kgf /cm) | ≥25 |

Elongation-break(%) | ≥ 425 |

Mold Making Silicon Rubber, Mold Making Silicone Rubber users instriction

Mold Making Silicon Rubber, Mold Making Silicone Rubber and silicon are generally named as two-part room temperature sulfurated silicone rubber, which features an exceptional fluidity and good operability.When mixed with 3%,5% curing agent, they can still be operated within 30 minutes,but will be formed after 2-3 hours.With resistance to deformation, high temperature, acid and alkali, and expansion, silicon flexible molds are used for mold duplication and delicate mold making for poli crafts, resin crafts lighting and candle crafts.

This product is a white or red flowable liquid with a hardness of 22,50A° when cured. If large products and therefore multiple-piece molds are needed by customers, silicone rubber with higher hardness will be required for the molds. Conversely, soft silicon is indispensable for molds with complicated pattern and delicate details. The amount of curing agent admixture depends on the actual need of customers. More will be added for speedy drying and fast release and less when otherwise.

Mold Making Silicon Rubber, Mold Making Silicone Rubber technical guidelines

1. Stir the base (Part A) well beofre use (except when depending on machine ).

2. Shake the catalyst container (Part B) well before use.

3. This is a 100 Part A to 3-5 Part B mixing ratio by weight.Weigh the desire amount of base into a clean mixing container.

4. Weight the proper amount of catalyst into the container. Mix the base and catalyst together by stirring with a stick until a uniform color is obtained. Scrape the container walls and bottom well to insure a thorough mix.

Mold Making Silicon Rubber, Mold Making Silicone Rubber feactures:

1.Two-part silicon rubber:flowable liquid silicon and curing agent.

2.Cures at room temperature within 2-4 hours.

3.An exceptional fluidity and good operability, easy to demold.

4.Good tensile and tear strength, low shrinkage.

5. High duplication times.

Any questions, please feel free to contact Ms. Judy

MOBILE: 0086-18938867591

Skype: judy.zhao723

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents