silicone rubber for mold making,RTV silicone for molding

- US $8.80

200 - 40,000 kilogram

- US $6.80

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY625

payment methodT/T, L/C, Westem Union

-

update timeTue, 05 Nov 2013 12:12:21 GMT

Paramtents

color white

HS code 39100000

sample available

normal packing 25kgs per drum

delivery within 3 days

usage for mold making

MOQ 200KG

Packging & Delivery

Min Order200 kilogram

Briefing

1. free sample

2. low shrinkage

3. high tear strength

4.favorable hardness

Detailed

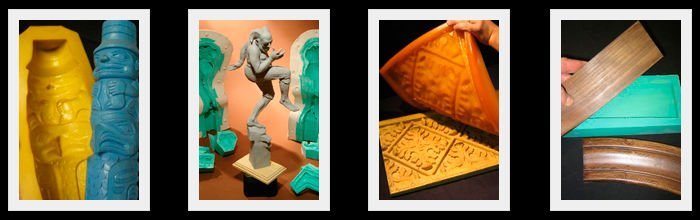

silicone rubber for mold making applications

silicone rubber for mold making is primarily intended for poly resin crafts, PU crafts, PU resin crafts ,gypsum crafts ,unsaturated resin crafts, lighting and candles crafts ,plastic toy , stationery gifts crafts industry, a large statue Buddha, furniture, furniture decorative materials, statues Buddha, artifacts copied, building decoration materials, largescale cement mold, artificial fossils Factory, Europe component factory,

simulation landscapes, animals and plants sculpture, sandstone crafts and so on.

silicone rubber for mold making description

silicone rubber for mold making is white or red flowing liquid with general hardness of 22-50 shore A after curing. tin cured silicone rubber is a kind elastic silicon rubber mold which features with resistance to deformation, high-temperature, acid-alkali and expansion as well as high reproduction times, good tensile strength, tear strength and elongation.

FAQ. Why the silicone rubber for mold making just can be reproduced for a few times?

It can be due to the following reasons:

a. Adding too much silicone oil in to silicon rubber. Silicon oil is an additive which destroies the molecular weight of silicone rubber and reduce the tension and tear strength.

b. Using the silicon rubber with a high hardness to make molds for small sized products with delicate and intricate designs and the silicon rubber with a low hardness to makes molds for large sized products with simple designs.

(Notes: we should choose the silicon rubber specifically according to the requirements of our products to avoid this problem.)

Datesheet of silicone rubber for mold making .

Property | 625# | 630# |

Hardness (Shore A) | 25 | 30 |

Tensile strength, MPa | 3.1 | 3.6 |

Elongation @ break, % | 580 | 550 |

Tear Strength (N/mm) | 25 | 32.6 |

Linear shrinkage (%) | 0.3 | 0.3 |

Viscosity | 19000-22000 | 23000-25000 |

Color | Off White | Off White |

Mixing ration | 100:5 | 100:5 |

Pot life | 40 minutes | 30 minutes |

Cure time | 4-5 hours | 4-5 hours |

The proportions and reactions of the curing agent and the silicon are listed as follows:

a. Adding curing agent 1%, the silicon can still be operated within 2.5 hours and can be demoulded after 6-8 hours.

b. Adding curing agent 2%, the silicon can still be operated within 50 minutes to 1 hour and can be demoulded after 2-3 hours.

c. Adding curing agent 3%, the silicon can still be operated within 28 - 30 minutes and can be demoulded after 1.5-2 hours.

d. Adding curing agent 4%, the silicon can still be operated within 10 - 15 minutes and can be demoulded after 1 -1.5 hours.

Any questions of silicone rubber for mold making , please feel free to contact Maggie:

TEL: 086-755-89948006

FAX: 086-755-89948030

MOBILE:086-18938867501

Website: www(dot)szrl(dot)net

E-MAIL: hysd(at)szrl(dot)net

You need a product

Related Searches

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents