Silicone Mold Making Rubber for Architectural Plaster Molds

- US $7.80

200 - 40,000 kilogram

- US $5.42

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelrtv 638#

payment methodT/T, L/C, Westem Union

-

update timeTue, 05 Nov 2013 12:15:57 GMT

Paramtents

color white

certifications Rosh,SGS,ISO9001:2000

operation way brushing way

hardness 33 shore A

shrinkage low shrinkage

visicosity light visicosity

deformation no deformation

shelf life 12 months

duplication times high duplication times

Packging & Delivery

Min Order200 kilogram

Briefing

high strength silicone

low viscosity

free cataly

Rosh,SGS,ISO

Detailed

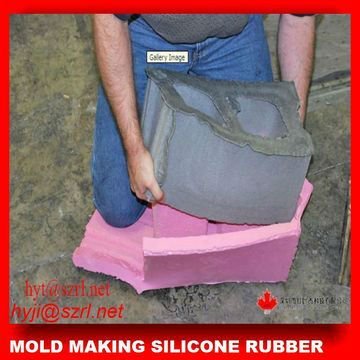

Silicone mold making rubber for architectural plaster molds

1.Mainly application of Silicone Mold Making Rubber for Architectural Plaster Molds

Silicone mold making rubber is a two part silicone rubber and curing with tin catalyst. As with a low viscosity,high tear strength and excellent duplication times,it's widely used for concrete casting,cement products casting,making molds for artificial stone,concrete crafts,cement crafts,GRC/GPR decorations,concrete statues and garden statues ect.

2.Features of Silicone Mold Making Rubber for Architectural Plaster Molds

Good cut-growth resistance

High durometer hardness

Low shrinkage

Easy release

Room temperature cure within 24 hours

Heat-accelerable cure

Long mold life

Highly detailed reproductions

Simplified handling

3.Technical datasheets of silicone mold making rubber rtv 638#

Model:638#

Appearance:white/red

Viscosity(cs):22000

Hardness(A):33

Tensile strength(kgf/cm)≥35-36

Elongation break(%):≥450

Retractility(%):≤0.3

Operate time(min):30

Curing time(hours):2-4

Mixing proportion of curing agent:4%

4.How to making architectural plaster molds with silicone mold making rubber?

1. Stir the base (Part A) well beofre use (except when depending on machine ).

2. Shake the catalyst container (Part B) well before use.

3. This is a 100 Part A to 4 Part B mixing ratio by weight.Weigh the desire amount of base into a clean mixing container.

4. Weight the proper amount of catalyst into the container. Mix the base and catalyst together by stirring with a stick until a uniform color is obtained. Scrape the container walls and bottom well to insure a thorough mix.

5.Though it is often unnecessary to deair the material due to its low viscosity some may choose to do so. If so,place the container into a vacuum chamber and evacuate the entrapped air from the mixture using a vacuum pump capable of achieving 29 inches of mercury vacuum.The mixture will rise, crest and then collapse in the contanier. Interruption(bumping) of the vacuum may be necessary to prevent overflowing the container. Keep the mixture under full vacuum for 2-3 minutes.

6. Bleed air slowly into the vacuum chamber. When the chamber is at atmospheric equiplibrium,remove the cover plate and take out the container.

7.Pour the deaired material slowly in a steady stream from one end of the mould so that the material flows evenly over the pattern. This should minimize emtrapment of air bubbles under the flowing material. A mold may be poured firstly over the pattern, which will also help reduce the possibility of entrapping air on the pattern and in the cured rubber.A mold release agent may be applied on the pattern first to improve release.

7.Shelf life of silicone mold making rubber

Twelve(12) months from date of shipment when stored at 250C in the original sealed packages.

8.Package style of silicone mold making rubber

Packed in clean 25kg/pail, 200kg/pail.

Any questions about Silicone Rubber, Leah is at your service.

TEL: 086-755-89212382

FAX: 086-755-89948030

MOBILE: 086-189 3886 7561

Website: www(dot)szrl(dot)net

E-MAIL: hyji(at)szrl(dot)net

Skype: leahchou1214

QQ: 189 3886 7561

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents