how to make a silicone moulds?

- US $8.80

200 - 40,000 kilogram

- US $6.60

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

model625#,628# silicone rubber

payment methodT/T, L/C, Westem Union

-

update timeTue, 05 Nov 2013 12:26:29 GMT

Paramtents

color all color available

certificate SGS, MSDS, RoHS, Reach

Application for sculpture ,gypsum mold ,rock mold ,etc

Payment T/T, Western Union, L/C

mixing ratio 1:1 or 10:1

sample free

package 25kg/drum 200kg/drum

HS Code 39100000

MOQ 200kg

catalyst 4% free

Packging & Delivery

Min Order200 kilogram

Briefing

1 mixing part A and part B evenly

2 do vacumming to drive away bubbles

3. take a molds out

Detailed

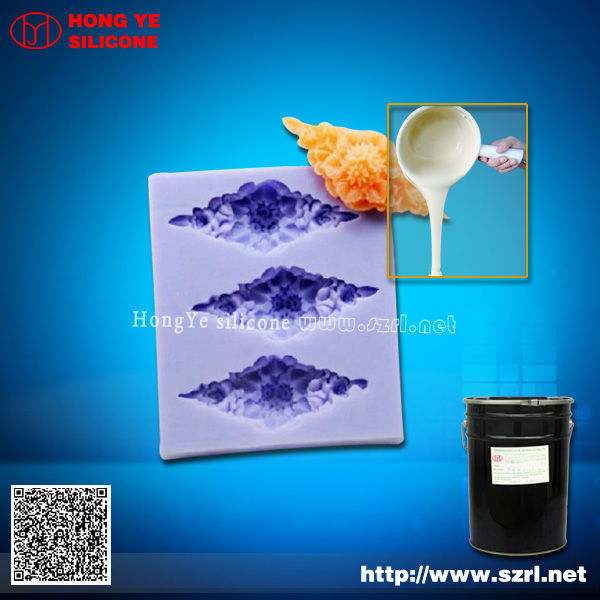

How to make a silicone moulds?

The operation instructions for how to make a silicone moulds?

The silicone moulds materials is a two-component flowing liquid, the component A is silicone rubber, and the component B is curing agent.

Mix the silicone rubber and the curing agent evenly, for example, take silicon rubber of 100g and add curing agent of 2g

(Notes: the silicone rubber and the curing agent must be mixed evenly, otherwise the mold will appear uncomplete curing phenomenon. The drying and uneven curing parts will influence the service life and molding times of the silicone rubber mold, and even causing mold wasting.)

Deairring and air bubble eliminating handling for silicone moulds

After the silicone rubber and the curing agent are mixed evenly, then take it to deair and eliminate air bubbles. The deairring process should not last too long and not exceed 10 minutes under the normal circumstances. If the deairing lasts too long, the silicone rubber will be cured at once after crosslinking reaction,thus, it is unable to brushing or pouring. In this case, the silicone rubber is wasted, the operation shall be restarted.

Brushing or pouring process to make a silicone moulds

put the deairred silicone rubber onto a product in a mode of brushing or pouring. (Release agent or insulating agent shall be applied on the product or model to be molded before pouring the silicone rubber.) Then, brush the silicone rubber onto the product evenly. 30 minutes later, apply a layer of glass fiber cloth to reinforce the tear and tensile strength of the silicone rubber. Repeatedly, brush another layer of silicone rubber and another layer of glass fiber cloth, it will be done after two times of brushing. In this case, the service life and the molding times of the silicone rubber mold are relatively improved much, the cost is saved and the efficiency is improved as well.

Outer mold making process for silicone moulds

The general method is as follows: One is to inclose the mold with plastic board or wooden plates, and fill up the mold frame with gypsum. The other is resin brushing way, that is to brush a layer of resin, and then a layer of glass fiber cloth, repeatedly two or three times is enough, and the outer mold is finished.

The mixing ratio and reactions of the curing agent and the silicone rubber are listed as follows:

1. Adding curing agent 2%, the silicone can still be operated within 50 minutes to 1 hour and can be demoulded after 2-3 hours.

2 Adding curing agent 3%, the silicone can still be operated within 28 - 30 minutes and can be demoulded after 1.5-2 hours.

3. Adding curing agent 4%, the silicone can still be operated within 10 - 15 minutes and can be demoulded after 1 -1.5 hours.

Tel: 0086-755-89948006

Fax: 0086-755-89948030

Key Words: liquid RTV silicone rubber , silicone rubber, liquid silicone rubber, rtv silicone rubber, how to make

silicone molds, silicone moulds, how to make a silicone mold, liquid silicone

You need a product

Related Searches

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents