mould making and casting material-silicone rubber

- US $8.00

200 - 40,000 kilogram

- US $5.80

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY6 series

payment methodT/T, L/C, Westem Union

-

update timeTue, 05 Nov 2013 12:34:54 GMT

Paramtents

color white

HS code 39100000

sample available

normal packing 25kgs per drum

delivery within 3 days

Shelf life One year

Certificant RoHS, Reach, MSDS,SGS.ISO9001:2008

application Mold making silicone materials

MOQ 200kgs

Packging & Delivery

Min Order200 kilogram

Briefing

1.Low shrinkage

2.Favorable tension

3.No deformation

4.good operability

Detailed

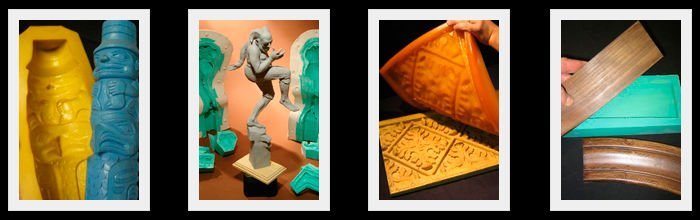

mould making and casting material has been used for more than 15 years to reproduce sculpture all over the world ranging in size from less than 1" (2.54 cm) to almost 400 feet high (120 m).

Today, mould making and casting material are used by thousands of sculptors and foundries for casting wax, resins, plaster, concrete and other materials to make accurate reproductions of original sculpture.

Project Specific - mould making and casting material wide range includes mold rubbers that can be poured on , brushed on , sprayed on or pressed on to any original sculpture and will reproduce detail perfectly.

mould making and casting material 625 TDS

Model | 625# |

Appearance | white |

Mixing proportion of curing agent(%) | 2-3% |

Operating time ( mins ) | 30-60 |

Curing time( hours ) | 6-8 |

Hardness (A°) | 25 |

Density ( g/cm 3) | 1.08 |

Viscosity (CS) | 19000 |

Tensile-strength ( kgf /cm2 ) | ≥40 |

Tear-strength (kgf /cm2 ) | ≥22 |

Elongation-break(%) | ≥400 |

Retractility(%) | ≤0.3 |

mould making and casting material features

mould making and casting material is white or red flowing liquid with general hardness of 22-50A°after curing.

mould making and casting material is a kind elastic silicon rubber mold which features as below:

- resistance to deformation,

- high-temperature resistance

- acid-alkali resistance

- expansion as well as high reproduction times,

- good tensile strength ,

- Strong Tear strength

- Good elongation

- Low shrinkage

- Long shelf time which can reach at least 1 year

mould making and casting material operations

If the customer wants to make large products and large size molds, the mold should be made of silicon rubber with high hardness. On the contrary, if the mold with fine and precision patterns, it should be made of silicon with low hardness. The amount of the curing agent depends on the actual requirements of the customer. If molds requiring fast drying and demold, more curing agent is needed; contrarily, if molds requiring slower drying and demold, less curing agent is needed.

(Note: our company does not recommend you to add silicone oil. If a special soft silicone mold or fine detailed and complex patterns products are required, 5%-10% silicone oil can be added to soften the mold for easy demold.)

Please dont hesitate to ask if you have any questions about mould making and casting material, here Cassi is at your service:

Tele: 86-755-8994-8013

Cell:86-13751020433

Email: hyjg(at)szrl(dot)net

You need a product

Related Searches

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents