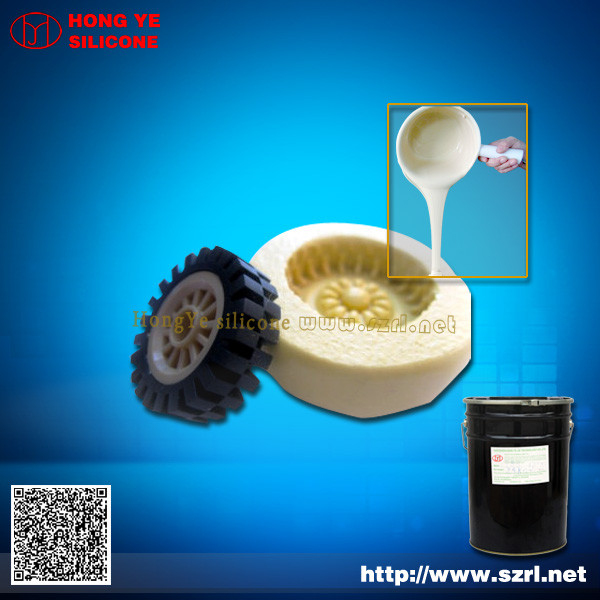

Manufacturer of Liquid Silicon for pouring mould

- US $8.90

200 - 40,000 kilogram

- US $6.50

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY638 silicone rubber

payment methodT/T, L/C, Westem Union

-

update timeTue, 05 Nov 2013 12:38:01 GMT

Paramtents

easy demould liquid

Packging & Delivery

Min Order200 kilogram

Briefing

easy demoulding

light viscosity

aging resistant

Detailed

HY-638 Liquid Silicon for pouring mould:

Product Details:

COLOR | WHITE/OFF-WHITE |

Place of Origin | Guangdong China |

Brand Name | Hong Ye Silicone Rubber |

Model Number | HY-638 SILICONE |

Payment & Shipping Terms:

Minimum Order Quantity: | 200 Kilogram 1 CBM CAN LOAD 500KGS CARGO |

Price: | FOB FOB Shenzhen USD 5.30~7.90 |

Packaging Details: | 25kg/drum or 200kg/drum |

Delivery Time: | 3 DAYS AFTER OUR BANK GOT YOUR PAYMENT |

Payment Terms: | L/C,T/T |

Supply Ability: | 8000 Kilogram per Day NEGOTIABLE |

Detailed Product Description:

HY-638 Liquid Silicon for pouring mould applicate:

Production mold casting wax, gypsum, concrete or resins (urethane, polyester, etc. ). Applications include reproducing sculpture, architectural restoration, making candle molds, casting pewter, place couldnt pour rubber over the above etc. For make a mold by brushing (or spraying) rubber onto the model. Rubber will hold a vertical surface and will reproduce the finest detail brushed onto the model in layers until a suitable thickness is built up. The rubber is allowed to cure and a support shell is applied prior to demold. The advantage of making a mold by brushing rubber onto the model is that it minimizes the amount of rubber used, saving material costs.

HY-638 Liquid Silicon for pouring mould fast sprayed rubber molds that have the best release properties for production casting of resins, plaster, etc. It is a tin silicone rubber that self-thickens for making concrete Spray able -on molds. Properly applied, Mixed 100A: 5B by weight, rubber quickly develops thixotropy when mixed in air. Cured with negligible shrinkage to a durable mold rubber good for production casting resins, foams, concrete, plaster and other materials. Application of a support shell is achieved by spraying over the rubber mold after it has fully cured.

HY-638 Liquid Silicon for pouring mould: Mix & Apply By Hand Silicone putties are two-component, tin-cure silicone putties that can be applied "on-site"--directly to almost any model; Capturing the finest detail and curing within minutes. Silicone Putty has been used to make molds of valuable antiques and archeological models and can be used to make fast molds of sculpture, prototypes, candles, picture frames, coins, etc. Also can cast wax, gypsum and a variety of resins into Putty molds.

HY-638 Liquid Silicon for pouring mould for poly crafts, lighting and candles, multiple piece molds for large product.

Model: 638 silicone rubber

Appearance: White

Mixing proportion of curing agent(%) 2

Operating time ( hours ): 0.5

Curing time( hours ): 2-4

Hardness (shore A): 28-32

Viscosity (CS): 28000-30000

Tensile-strength ( kgf /cm2 ): ≥35

Tear-strength (kgf /cm2 ): ≥20

Elongation-break(%): ≥ 470

Retractility(%): ≤0.3

Packing (kg/pail ): 25, 200

The datasheet just for reference,need more information,please feel free to contact us,we can produce silicone follow your request.

HY-638 Liquid Silicon for pouring mould using instruction:

Component A is white flowing liquid and component B is the curing agent. For example, take silicone rubber of 100g and add 2g curing agent for mixing evenly (silicone rubber and curing agent must be measured accurately). After the silicone rubber and the curing agent are completely mixed, put the silicon into a vacuum machine for deairing to remove the bubbles. After deaired, pouring the liquid silicone rubber into the product to be duplicated or into the mold frame. If you don't have vacuum machine, please add 1.2% or 1.5% curing agent so that the bubbles can bubble itself. Since the less curing agent you add, the slower the mould will curdle, the bubbles will bubble out itself.

Any questions,please feel free to contact Ms Judy

MOBILE:086-18938867591

QQ: 18938867591

Skype: judy.zhao723

You need a product

Related Searches

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents