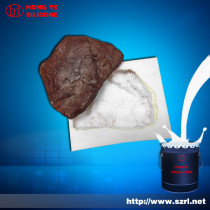

Pouring Mold Silicone Rubber raw material

- US $9.98

200 - 40,000 kilogram

- US $4.98

40,001 - 999,999 kilogram

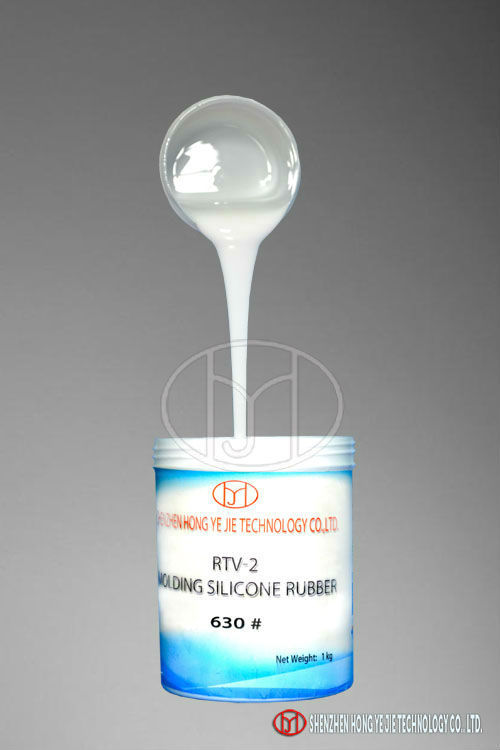

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelmolding silicone rubber

payment methodT/T, L/C, Westem Union

-

update timeTue, 05 Nov 2013 13:05:33 GMT

Paramtents

Certification SGS,MSDS,RoHS

HARDNESS 18-40A

Mixing Ratio 2%

Type silicone rubber

Appearance Fluid

Application Mold making materials

Certificated RoHS, Reach, MSDS,SGS.ISO9001:2008

EINECS No 39100000

Purity 100%

Curing agent 5%for free charged

Packging & Delivery

Min Order200 kilogram

Briefing

2.light viscosity and good flowability

3.low shrinkage

4.favorable tension

5.high hardness for large crafts

Detailed

Pouring Mold Silicone Rubber raw material

Pouring Mold Silicone Rubber raw material Applications:

Pouring molding silicone rubber material is mainly used for many kinds products mold making in pouring way, such as toys, gifts, decoration, plate engrave, human replica, art crafts, resin crafts, poly resin crafts, unsaturated resin crafts, candle crafts, plastic crafts, stationeries, plaster crafts and buddhist statue crafts, etc.

Pouring mold Silicone Rubber raw material Features:

620# pouring mold silicone rubber, with hardness of 18-22 shore A, is particulary suitable for mold making for small-sized (less than 30cm) crafts with complicated designs;

625# pouring mold silicone rubber, with hardness of 23-26 shore A, is suitable for mold making of small & medium-sized(less than 50cm) products with simple and complicated designs;

640# pouring mold silicone rubber, with hardness of 38-42 shore A, is applicable to making molds for large crafts with simple designs, especially the products larger than 100cm.

Pouring mold Silicone Rubber raw material Advantages:

Light viscosity;

Pourable effort;

Good fluidity;

Easy-operation;

Good tensile and high tear strength;

High reproduction times;

Resistance of high temperature.

How to Make Silicone Molds in Pouring Way?

RTV-2 molding silicone rubber contains two parts: part A is liquid silicone rubber, part B is curing agent.

1. Prepare the original molds: You must make sure the original molds is perfect and fix it on a board, stick the board with mold to another board, and make a frame with four pieces to enclose the molds;

2. Clean the original mold with soap water, and dry it, then evenly brush a lay of mold release agent;

3. Mix both A and B parts totally by weight at the ratio of 100:2-5 (A to B)in a clean container(weight of part B is always depending on your local temperature. Basically, we advise you add 5%part B at the room temperature 25C; if the temperature is more than 30C, we advise you add less part B; if temperature lower than 15C, we advise you add more part B). Making sure that A and B mixed evenly, otherwise the compound will be partly solidified and this will give birth to difficulties in the following operations, leading to the short life of your final molds.

4. Degas the compound by a vacuum pump about 3-5 minutes(usually no more than 10 minutes), otherwise, it will cause cross linking reaction, and no more further operations will be available.

5. Pour the mixed and degased silicone rubber into the frame slowly and evenly. 30-45 minutes later, you can demould the mold and use a knife to remove the surplus silicone in the edges.

6. Take it into mass production after 24 hours.

You need a product

Related Searches

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents