Silicone Mold Making RTV-2 for decorative concrete molds

- US $12.30

200 - 40,000 kilogram

- US $4.89

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY625 RTV-2 silicone

payment methodT/T, L/C, Westem Union

-

update timeTue, 05 Nov 2013 13:11:00 GMT

Paramtents

CAS No. Silicone Mold Making RTV-2

Other Names RTV-2 silicone

MF silicone rubber

EINECS No. liquid silicone rubber

Grade Standard Agriculture Grade,Food Grade,Industrial Grade,Medicine Grade

Purity 25 shore A

Appearance clear silicone,white

Application for mold making

item No. HY625

Usage for toys ,crafts,plaster mold making

Mixing 4%

Viscosity (mPas -25 0C) 18000±2000

Tensile-strength(kgf /cm2 ) ≥36

Tear-strength (kgf /cm ) ≥27

Elongation-break(%) ≥ 450

Retractility(%) ≤0.25

Hardness (A°) 25

Packging & Delivery

Min Order200 kilogram

Briefing

no deformation

low shrinkage

high tear strength

Free catalyst

Detailed

Silicone Mold Making RTV-2 for decorative concrete molds

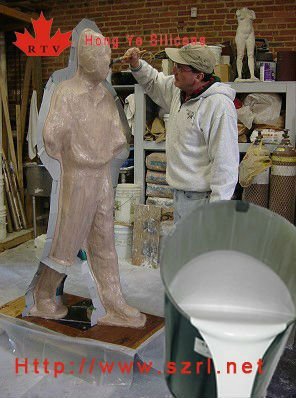

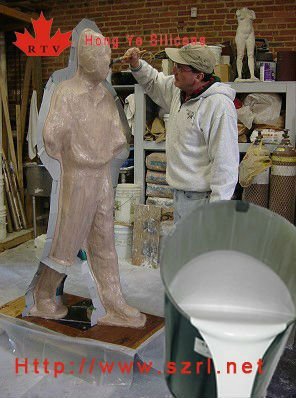

Silicone Mold Making RTV-2 is mainly used for decorative concrete molds,crafts ,unsaturated resin crafts, lighting and candles crafts ,plastic toy , stationery gifts crafts industry, a large statue Buddha, relievo furniture, furniture decorative materials, statues Buddha, artifacts copied, building decoration materials, large-scale cement mold, artificial fossils Factory,Europe component factory, simulation landscapes, animals and plants sculpture, sandstone crafts and so on.

Silicone Mold Making RTV-2 for decorative concrete molds FEATRURE

Silicone Mold Making RTV-2 is white or translucent flowing liquid with general hardness of 22-50shore A after curing. Molding silicone rubber is a kind elastic silicone rubber mold which features with resistance to deformation, high-temperature, acid-alkali and expansion as well as high reproduction times, good tensile strength ,tear strength and elongation, Stripping the gender is good, Linear shrinkage rate low, Size stability is good.

Note: according to user's requirements, production, commissioning, different color and performance products

FAQ of Silicone Mold Making RTV-2 for decorative concrete molds

Why should the silicone mold be reused only for a few times?

It can be due to the following reasons:

a. Adding too much silicone oil in to silicone rubber.

b. Using the silicone rubber with a high hardness to make molds for small sized products

with delicate and intricate designs .

Payment: cash, bank transfer, the collection of money, pay treasure, paypal

Packing: 25KG, 200KG

Quality/security authentication: the RoHS, MSDS, SGS

Sample: free

Delivery time: three days

Datasheet of Silicone Mold Making RTV-2 for decorative concrete molds

788# white, the usage for poly crafts, lighting and candles, multiple piece molds for large product.

Model: 788 silicone rubber

Appearance: White

Mixing proportion of curing agent(%) 2

Operating time ( hours ): 0.5

Curing time( hours ): 2-4

Hardness (shore A): 28-32

Viscosity (CS): 28000-30000

Tensile-strength ( kgf /cm2 ): ≥35

Tear-strength (kgf /cm2 ): ≥20

Elongation-break(%): ≥ 470

Retractility(%): ≤0.3

Packing (kg/pail ): 25, 200

The datasheet just for reference,need more information,please feel free to contact us,we can produce silicone follow your request.

Silicone rubber using instruction on Silicone Mold Making RTV-2 for decorative concrete molds

Component A is white flowing liquid and component B is the curing agent. For example, take silicone rubber of 100g and add 2g curing agent for mixing evenly (silicone rubber and curing agent must be measured accurately). After the silicone rubber and the curing agent are completely mixed, put the silicon into a vacuum machine for deairing to remove the bubbles. After deaired, pouring the liquid silicone rubber into the product to be duplicated or into the mold frame. If you don't have vacuum machine, please add 1.2% or 1.5% curing agent so that the bubbles can bubble itself. Since the less curing agent you add, the slower the mould will curdle, the bubbles will bubble out itself.

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents