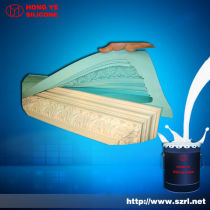

liquid silicone rubber (LSR) for various molds making

- US $8.38

200 - 40,000 kilogram

- US $6.89

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY940

payment methodT/T, L/C, Westem Union

-

update timeTue, 05 Nov 2013 13:13:47 GMT

Paramtents

color:any transport:by sea

Certifications:RoHS.SGS ISO9001:2000 provide curing agent for free

HS 31900000

application mold making

shelf life 1 year

MOQ 200kg

appearance transparent

Packging & Delivery

Min Order200 kilogram

Briefing

1,easy to demold

2,Good tensile and tear strength

3,low shrinkage.

4,High duplication times

Detailed

Medical-Grade mask liquid silicone rubber (lsr)

Specifications

Light viscosity and good flowability;

Low shrinkage;

Favorable tension;

No deformation;

High temperature resistance.

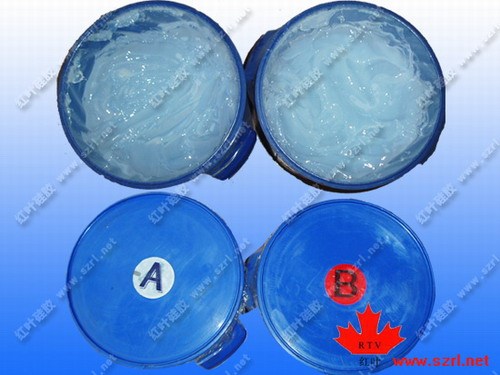

Injection moulding silicone rubber HY-940 Standard Datasheet for medical grade:

Appearance | Viscosity (cP) | Density g/cm3 | Hardness(Shore A) | Elongation(%) | Tear Strength(kN/m | |

HY-940 | Transparent | 600 | 1.08 | 40 | 550 | 35 |

Application

1.Separate or wipe clean the toolsof part A,B before use , orit may cause the product can’t working normally because of the A&B mixedand local agglomeration

2.The effective operating time is 4hours after the uniform mix between part A&B

3.During the rubber operation, avoidcontact the compounds which contains the N, S, P, Sn, etc, or it will causeincomplete curing or not curing.

4.The best mix ratio is A/B=1:1, toolarge or too small will influence the final product performance

How to use

1.Mixed A with Baccording to mixing ratio of 1:1 through the static mixer,then injectingthe mixed rubber into the mold through the injection machine, the rubber mustbe full filled(hand-mixing isfeasible, poured into the mold for molding)

2.Recommendedmolding conditions: 140°C/40-60s (thickness 2mm).

3.Testand determine the specific conditions of molding according to the thickness orsize of product

4.Ifthe bonding between the special material and silicone rubber is needed(e.g. PET,PC, iron andsteel materials, etc.you can check the accessory products of the silicone adhesive about our company )

Storage

Safe

1.Note the labor wearable during the application, avoid high-temperatureburns during the construction process, and prohibit consumption.

2.Use the product carefully, note the safety issues before and during use, moreover, follow the relevant provisions of national or local government safetyregulations. (Refer to the appropriate safety guidelines for details in MSDS)

Any questions of injection silicone rubber , please feel free to contactMr Allen :

TEL: 0086-755-89212365

FAX: 0086-755-89948030

MOBILE: 0086-18938861889

injection silicone rubber for mold making

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents