HY liquid latex rubber for Gypsum Molds

- US $7.85

200 - 40,000 kilogram

- US $6.95

40,001 - 999,999 kilogram

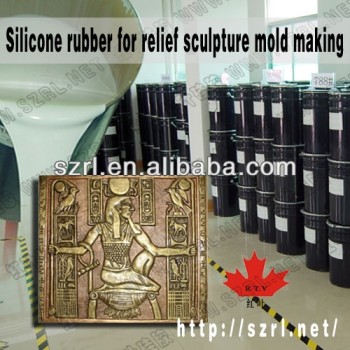

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY-625

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 14:14:11 GMT

Paramtents

Certifications: RoHS.MSDS.SGS ISO9001:2000

MOQ 200KGS

HS CODE 39100000

feature liquid

color white

Packging & Delivery

Min Order200 kilogram

Briefing

1.high reduplication times

2.good operabllity

3.exceptional fluidity

4.low shrinkage

Detailed

Specifications

Liquid Siliocne

1.good tensile strength

2.good tear strength

3.Stripping the gender is good,

4.Linear shrinkage rate low

liquid latex rubber applications

liquid latex rubber is primarily intended for poly resin crafts, PU crafts, PU resin crafts, gypsum crafts, unsaturated resin crafts, lighting and candles crafts, plastic toy, stationery gifts crafts industry, a large statue Buddha, relievo furniture, furniture decorative materials, statues Buddha, artifacts copied, building decoration materials, large-scale cement mold, artificial fossils Factory, Europe component factory, simulation landscapes, animals and plants sculpture, sandstone crafts,etc.

liquid latex rubber features

liquid latex rubberis white or red flowing liquid with general hardness of 15-40 shore A, after curing. Molding silicon rubber is a kind elastic silicon rubber mold which features with resistance to deformation, high-temperature, acid-alkali and expansion as well as high reproduction times, good tensile strength, tear strength and elongation.

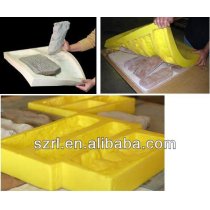

liquid latex rubber operations

If the customer wants to make large products and large size molds, the mold should be made of liquid silicone rubbers with high hardness. On the contrary, if the mold with fine and precision patterns, it should be made of silicon with low hardness. The amount of the curing agent depends on the actual requirements of the customer. If molds requiring fast drying and demould, more curing agent is needed; Contrarily, if molds requiring slower drying and demould, less curing agent is needed.

Dasheet of liquid latex rubber HY630

Model | 630# |

Appearance | white |

Mixing proportion of curing agent (%) | 5% |

Operating time (mins 25 0C ) | 20-40 |

Curing time(hours 25 0C) | 3-5 |

Hardness (A°) | 30±2 |

Density ( g/cm 3 ) | 1.08 |

Viscosity (Mpas -25 0C) | 27000-32000 |

Tensile-strength(kgf /cm2 ) | ≥40 |

Tear-strength (kgf /cm ) | ≥30 |

Elongation-break(%) | ≥ 450 |

Retractility(%) | ≤0.3 |

.

Frequently asked questions ofliquid latex rubber

Why does the liquid latex rubber mold have few molding times?

Theliquid latex rubberhas few molding times is due to follwoing reasons: adding too much silicone oil which will destroy the molecular of silicone rubber; making the mold for small and fine detailed products with higher hardness silicone rubber which is easy to break; making the mold for large products with soft silicone rubber which will reduce the tensile and tear strength of the mold, and the mold will have deformation.

FAQ of Liquid silicone for gypsum column mold making in China

Why should the silicone mold be reused only for a few times?

It can be due to the following reasons:

a. Adding too much silicone oil in to silicone rubber.

b. Using the silicone rubber with a high hardness to make molds for small sized products

with delicate and intricate designs .

Payment: cash, bank transfer, the collection of money, pay treasure, paypal

Packing: 25KG, 200KG

Quality/security authentication: the RoHS, MSDS, SGS

Sample: free

Delivery time: three days

Any questions, please feel free to contact Brook :

TEL: 086-755-89948294

FAX: 086-755-89948030

Mobile:86-18938867579

Email: hyjw(at)szrl(dot)net

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents