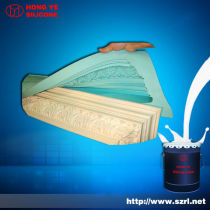

silicone for ornamental mouldings

- US $8.38

200 - 40,000 kilogram

- US $7.58

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY638#silicone rubber

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 15:40:07 GMT

Paramtents

color white

hardness 38 shoreA

mixing ratio 100:3

operation way brushing

Viscosity (CS) 23000±3000

Tensile-strength( kgf /cm2 ) ≥48

Tear-strength (kgf /cm2 ) ≥28

Elongation-break(%) ≥400

Curing time(hours 25 0C) 4-6

Application Most suitable for large sized product by pouring or brushing method

Packging & Delivery

Min Order200 kilogram

Briefing

1)light viscosity

2)low viscosity for easy mixing and pouring

3)negligible shrinkage

Detailed

1. silicone for ornamental mouldings applications:

RTV2 silicone rubber is kind of moulding material which is good for replication of detailed pattern cornices, center pieces, polyurethane mouldings, castings, ceiling roses, decorative gypsum mouldings, plaster mouldings as well as door surounds and window mouldings. dado rails,stone sculptures and so on.

Easy to make molds. Sell one piece, you can get the whole pay.

2. silicone for ornamental mouldings description:

Mold making silicone rubber rtv-2 is white or red flowing liquid with general hardness of 15-50 shore A after curing. Molding silicon rubber is a kind elastic silicon rubber mold which features with resistance to deformation, high-temperature, acid-alkali and expansion as well as high reproduction times, good tensile strength, tear strength and elongation.

3. silicone for ornamental mouldings operations:

- 1. get necessary tools prepared, clean the original model thoroughly and fix it on the wooden board.

- 2. Brush a layer of mold releasing agent ( Vaseline) on the surface of the original product, cut proper size of hard paper board according to the height of model, enclose it.

- 3. Choose the right type/model of silicone based on size, structure, pattern and application of the product. Here we use silicone J-1225 (or J-1220) of Jenova Brand, add 2%-5% catalyst into the silicone, blend it evenly and then put it into vacuum pumping machine to deair.

- 4. Pour the vacuumized silicone onto the products, get products fully and evenly flooded.

- 5. after the silicone cured completely, pull down the paper boards, you can take out your products, then a mold is formed.

- 6. note: Generally, in this pouring way, you should use low-hardness silicone rubber to make molds, so it will be easier to demould and will not destroy the products.

Notes of silicone for ornamental mouldings operations

Our company does not recommend you to add silicone oil. If a special soft silicone mold or fine detailed and complex patterns products are required, 5%-10% silicone oil can be added to soften the mold for easy demold.

4.Frequently asked questions of silicone for ornamental mouldings :

Why does the silicone rubber mold have few molding times?

The silicone rubber mold has few molding times is due to follwoing reasons: adding too much silicone oil which will destroy the molecular of silicone rubber; making the mold for small and fine detailed products with higher hardness silicone rubber which is easy to break; making the mold for large products with soft silicone rubber which will reduce the tensile and tear strength of the mold, and the mold will have deformation. Thus, we should take the proper silicone rubber to make the mold for suitable products.

Minimum Order Quantity: 200 Kilogram

Packaging Details: 20kg/drum and 200kg/drum

Delivery Time: within 3 days after payment confirmed in our bank.

If you have any questions with silicone for ornamental mouldings , pls feel free to contact Ms Angel

Tele: 0086-755-8994-8019

Fax:0086-755-8994-8030

Cell:0086-18938867575

Email: hysa(at)szrl(dot)net

Trademanager:cn200039753

You need a product

Related Searches

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents