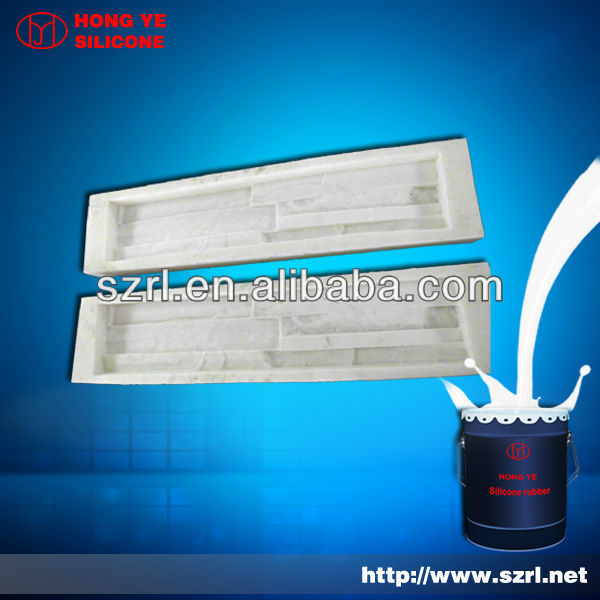

concrete stone moulding silicone

- US $8.38

200 - 40,000 kilogram

- US $7.38

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY628# silicone rubber

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 15:40:34 GMT

Paramtents

CAS No. RoHS,MSDS,SGS,ISO9001:2000

Purity 100%

sample available

HS Code 39100000

Hardness (A°) 28±2

Viscosity (CS) 25000±2000

Mixing Ratio of silicone and catalyst 100:3

Operating time (mins 25 0C ) 30-45

Curing time(hours 25 0C) 6-8

Packaging Details Packaging Details

Packging & Delivery

Min Order200 kilogram

Briefing

1)light viscosity

2)low viscosity for easy mixing and pouring

3)negligible shrinkage

Detailed

concrete stone moulding silicone application:

Liquid silicone rubber for artificial stone making find applications for moulding a variety of materials some are shown below:

MaMterial | Application |

Wax | soaps, Candles and use in the lost wax process for bronze casting |

Polyurethane | Mirror and picture frames, architectural mouldings |

Polyester resin | Giftware, figurines, sculptures modelling |

Gypsum/plaster | Covings and cornices, film studios, architectural decorative mouldings, figurines, fireplaces |

Ceramics | Earthenware pottery |

Low melt alloys | Toys, models, bronze casting, brass casting |

Glass | Auto windscreens |

Stone filled resins | Replication of works of art, fireplaces |

concrete stone moulding silicone features:

· Lower costs

· Broader product range

· Less sensitive to exact mix ratio

· Easy to use thixotroping agent available

· Accelerator catalysts available to speed up cure

Mixing of grades possible to achieve desired hardness

concrete stone moulding silicone specifications:

Model | Color | Mixing ratio (%) | Pot life (mins) | Demould time ( hrs) | Hardness ( A0) | Tensile-strength (kgf/cm2) | Tear-strength (kgf/cm) | Viscosity (cps) | Shrinkage rate (%) | Elongation (%) |

625# | white | 100 : 4 | 30 | 4-6 | 25 | ≥ 41 | ≥ 31 | 21000 | ≤0.3% | 450% |

630# | white | 100: 4 | 30 | 4-6 | 30 | ≥ 47 | ≥ 35 | 24000 | ≤0.3% | 430% |

How to avoid air bubbles in silicone molds and models?

1)apply a thin layer of silicone to the frame and the model before pouring the full amount;

2)raise the silicone about a foot in the air and pour it slowly;

3)remove air or deair the silicone rubber with a vacuum pump within 10 minutes.

4)hold the box at an angle and pour the silicone in on the raised end.

Packaging Details:25kg/drum and 200kg/drum

Delivery Time:within 3 days after payment confirmed in our bank.

Payment Terms:L/C at sight, T/T, West Union

Supply Ability:8 Ton per Day

Storage and Shelf life: one year in cool dry place

If you have any questions with concrete stone moulding silicone, pls feel free to contact Ms Angel Yue

MSN: angelfly369(at)msn(dot)cn

Skype:angelfly369

Email:hysa(at)szrl(dot)net

Tel:0086-755-89948006

Mob: 086-18938867575

Trademanager:cn200039753

You need a product

Related Searches

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents