Molding silicone for cultural stone making

- US $9.80

200 - 40,000 kilogram

- US $6.80

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY625 HY630

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 15:42:21 GMT

Paramtents

color as request

catalyst free charge

sample available

mix ratio 100:3

hardness 10-40 shore A

shelf 12 months

package 25kg and 200kg per drum

Certification ROHS.MSDS.SGS ISO9001:2000

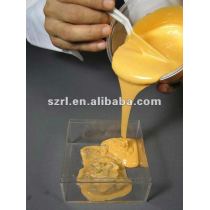

operation pouring and brushing

MOQ 200kgs

Packging & Delivery

Min Order200 kilogram

Briefing

Detailed

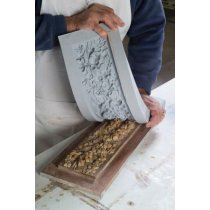

Description of Molding silicone for cultural stone:

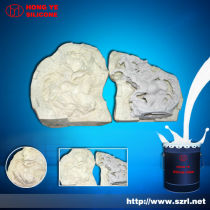

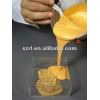

Molding silicone for cultural stone is white flowing liquid with general hardness of 22-50A°after curing. Molding silicon rubber is a kind elastic silicon rubber mold which features with resistance to deformation, high-temperature, acid-alkali and expansion as well as high reproduction times, good tensile strength , tear strength and elongation.

Models of Molding silicone for cultural stone

Model: 630# Molding silicone for cultural stone

Appearance: White

Viscosity (CS): 28000-32000

Hardness (A): 30

Tensile strength(kgf/cm2 ) ≥41

Tear strength (kgf /cm): ≥30

Elongation break(%): ≥470

Retractility (%): ≤0.2

Curing agent mixed rate (%): 2-3

Operate time (min): 30

Curing time (hours): 2-4

Model: 638# Molding silicone for cultural stone

Appearance: White

Viscosity (CS): 32000-35000

Hardness (A): 32-35

Tensile strength(kgf/cm2 ) ≥38-24

Tear strength (kgf /cm): ≥26

Elongation break(%): ≥350

Retractility (%): ≤0.2

Curing agent mixed rate (%): 5

Operate time (min): 50-70

Curing time (hours): 5-6

Features of Molding silicone for cultural stone:

Company Profile

We are manufacturer specializing in molding silicone rubber, mold duplicating rubber for resin craft makers,

special silicon for manual molding, shoe mold rubber, pad printing silicone, encapsulants and potting compound,

addition cure liquid silicone,baby nipple silicone rubber ,lifecasting,food grade silicone rubber, trademark silicone rubber,

HTV silicone rubber, lead-zinc alloy crafts silicone rubber, hot stamping silicone plate, hot stamping silicone roller, gross rubber,

RTV-2 silicone rubber, silicone molds, silicone products,etc.

silicone rubber package details

silicone rubber certifications:

SGS

ROSHS

FDA

ISO900

We can provide good solution for you , if you have question about how to make silicone mold , or how to use the silicone mold ,and any problem about the silicone mold , pls kindly feel free to let us know , we will be happy to serve you.

Any questions of Molding silicone for cultural stone making, please feel free to contact Kaimi:

MOBILE:0086-18938867528

E-MAIL: hyju(at)szrl(dot)net

skype:hyjiangying

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents