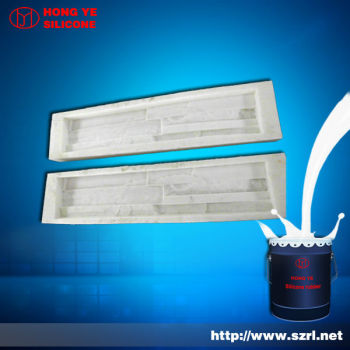

Addition molding silicone rubber for architectural stone

- US $11.55

200 - 40,000 kilogram

- US $8.88

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelE625#

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 15:45:43 GMT

Paramtents

Color high translucent

silicone rubber:curing agent 1:1

Certification SGS,MSDS,RoHS

Material 100% silicone

Classification Chemical Auxiliary Agent

Chemical Auxiliary Agent Fluid

Appliacation addition silicone for molding

MOQ 200 kgs

Port shenzhen

Packging & Delivery

Min Order200 kilogram

Briefing

1,exceptional fluidity

2,good operability

3,Nontoxic&Food grade

4,heat-ageing resistance

Detailed

Addition molding silicone rubber for architectural stone Applications:

Addition molding silicone could be mainly used for making concrete stones, precision molds, PU molds, for life casting, fabric finishing,shoe insoles making, seal for electronic components and solar circuit board, trademark decoration. etc.

Addition molding silicone rubber for architectural stone description:

Addition cure silicone rubber,Addition silicone,Platinum cure silicone are generally named as two-part addition silicone rubber that vulcanises at room temperature.Part A is a flowable liquid, part B is the curing agent(platinum catalyst). It features an exceptional fluidity ,good operability,excellent physical properties and very low shrinkage. The mixing ratio between Part A and Part B can be 10:1 or 1:1.

Addition molding silicone rubber for architectural stone feature:

Good fluidity and good operability and good for pouring method.

Excellent mechanical properties, in particular tear strength and tensile strength.

Excellent flexibility and it is easy to demould.

High temperature resistance, high duplication times and repeated use.

There are a range of catalysts/curing agent/hardener allows the Liquid rtv silicone rubber to fulfill Requirements for various applications and various requirements on the operation time and curing time.

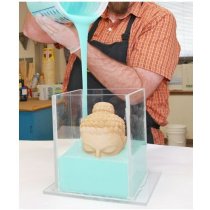

Addition molding silicone rubber for architectural stone operation:

1.The cast pouring, for example:

Prepare a frame, fix the prototype for copy into the frame, (if the prototype’s material is glass or ceramic, the release agent is necessary to prevent sticking.

2. Take 1 part A and 1 part B,mix themevenly.

3.Vacuum defoaming in 1~3 min,inject the rubber into the type box, then vacuum defoaming again, curing 24 hours in nature room temperature, use it after demold.

4. Demold after 3 hours’ room temperature curing, and then use it after 24 hours’ keep mold under the same condition.

You can also send me E-mail by scanning 2-Dimensional Bar Code below:

Addition molding silicone rubber for architectural stone package:

Addition molding silicone rubber for architectural stone certification:

Our factory:

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents