High strength Wacker Silicone for Resin Sculpture Mold Making

- US $9.80

200 - 40,000 kilogram

- US $6.50

40,001 - 999,999 kilogram

group nameRTV-2 silicone rubber for molds making

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY625 HY630

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 16:09:23 GMT

Paramtents

certification RoHS, Reach, MSDS,SGS.ISO9001:2008

color any

EINECS No 39100000

HARDNESS 18-40A

Appearance Fluid

Application High Tear Silicone for Mold making

sample available

catalyst free of charge

mix ratio 100:3

shelf life 12 month

Packging & Delivery

Min Order200 kilogram

Briefing

2. high reproduction times

3. good tensile strength

4. exceptional fluidity

Detailed

Datesheet of High strength wacker silicone for resin sculpture mold making:

Property | 625# | 630# |

Hardness (Shore A) | 25 | 30 |

Tensile strength, MPa | 3.1 | 3.6 |

Elongation @ break, % | 580 | 550 |

Tear Strength (N/mm) | 25 | 32.6 |

Linear shrinkage (%) | 0.3 | 0.3 |

Viscosity | 19000-22000 | 23000-25000 |

Color | Off White | Off White |

Mixing ration | 100:5 | 100:5 |

Pot life | 40 minutes | 30 minutes |

Cure time | 4-5 hours | 4-5 hours |

why chose High strength wacker silicone for resin sculpture mold making

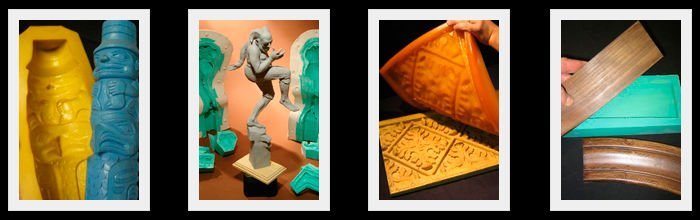

silicone rubber for art craft molding is an effective and inexpensive way to create multiple copies of a master prototype part when you need a spec-like material for multiple sets, in a short timeframe, for less than a traditional tool would cost.

liquid silicone rubber for molding are capable of reproducing remarkable detail, and because of the flexibility of silicone, draft angles, inserts, and undercuts are not as critical as in other molding processes.

How to making silicone molds with liquid Silicone rubber,rtv silicone,rtv-2 silicone rubber,silicone rubber rtv 2

(1) Smooth the original moulds.

(2) Brush on release agent.

(3) Correct weigh.

(4) Stir the two component evenly.

(5) vacuum-pumping.

(6)Brushable or pourable.

Frequently asked questions of High strength wacker silicone for resin sculpture mold making

Why does the silicone rubber mold have few molding times?

The silicone rubber mold has few molding times is due to follwoing reasons: adding too much silicone oil which will destroy the molecular of silicone rubber; making the mold for small and fine detailed products with higher hardness silicone rubber which is easy to break; making the mold for large products with soft silicone rubber which will reduce the tensile and tear strength of the mold, and the mold will have deformation. Thus, we should take the proper silicone rubber to make the mold for suitable products.

Why does the silicone mold get burnt out?

This consequence happens only because you have left out the important notes when using unsaturated resin materials to produce your products. The unsaturated resin produces great heat when added the curing agent. So you must demould the product within 3 minutes to avoid this problem.

Any questions of High strength Wacker Silicone for Resin Sculpture Mold Making, please feel free to contact Kaimi:

FAX: 086-755-89948030

MOBILE:086-18938867528

E-MAIL: hyju(at)szrl(dot)net

skype:hyjiangying

Place of Origin Guangdong China

Brand Name Hong Ye Silicone Rubber

Packaging Details: 20kg/drum and 200kg/drum

Delivery Time: within 3 days after payment confirmed in our bank.

Payment Terms: L/C,T/T

Supply Ability: 8 Ton per Day

Certifications:RoHS.MSDS.SGS ISO9001:2000

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents