Addition Cure Encapsulant & Potting Compound

- US $30.50

200 - 40,000 kilogram

- US $9.88

40,001 - 999,999 kilogram

group nameAddition cure silicone rubber

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelLiquid Silicone

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 16:38:44 GMT

Paramtents

Color high translucent

Certification SGS,MSDS,RoHS

Material 100% silicone

Certificate SGS

Classification Chemical Auxiliary Agent

Appearance Fluid

Pakage 5kg/drum 20kg/drum 200kg/drum

Price Negotiable

Sample sample for testing is available

Packging & Delivery

Min Order200 kilogram

Briefing

2.Good tensin strength

3.High tear strength

4.Pourable effect

5.High translucent

Detailed

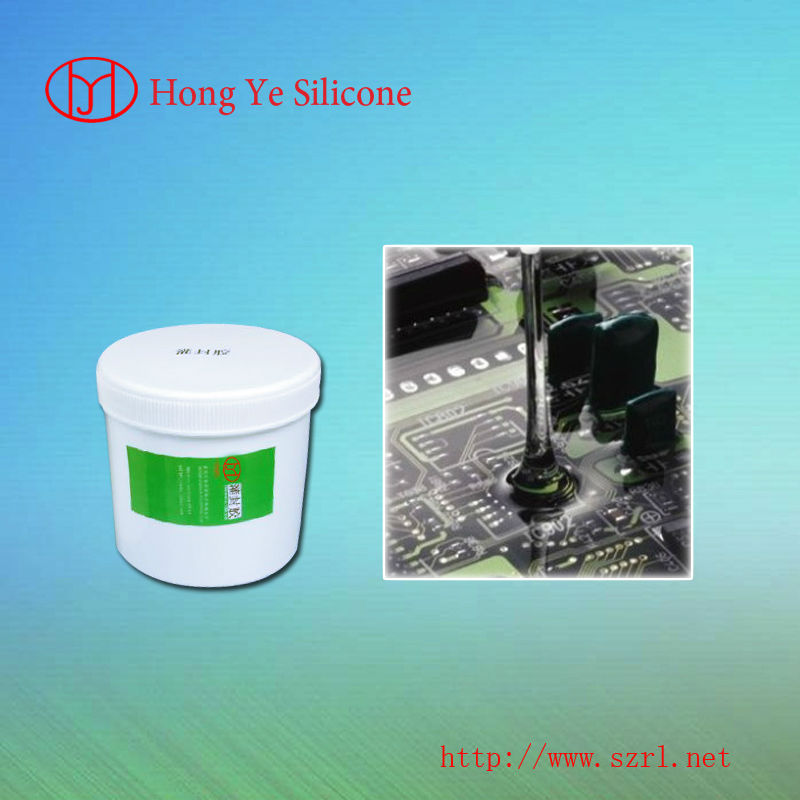

Addition cure encapsulant & potting compound

Number:hy9055

Usage:

filling for LED,LCD electronic display,circuit board.

Applications of Addition Cure Encapsulant & Potting Compound

it is applicable to sealing,bonding,coation for electronic parts.

hy9055 is two-component addition cure silicone rubber which can be divided into a transparent type and a flame resistant type.the product,which can be vulcanized under room temperature or moderate temperature with low viscosity,easy mixing and pouring,is applicable to bulk pouring with excellent electrical performanc.

Features of Addition Cure Encapsulant & Potting Compound

the product has low shrikage and non-corrosive,the silicone rubber can be used for a long period at the temperature of -60-----200 degree celsius with the characteristics of moisture-proof and waterproof ,radiation-proof as well as weatherable and anti-ageing.

(note:vulcanizing under the room temperature or heat curing according to different requirements.)

using instruction of Addition Cure Encapsulant & Potting Compound

1.mix the component A and component B evenly according to the proportion and can be used after deaired.

2.the vulcanizing time depends aon the temperature in case of heat curing is required.the higher the temperature,the shorter the vulcanizing time.and the thicker the product,the longer the time.

3.the flame resistant type silicone may produce deposit after-long-time placement,mix the component A and component B respectively and evenly according to the proportime before using.

Standard Datasheet:

Model | HY-9055 | |

Type | General purpose | |

Component | A | B |

Appearance(liquid) | Gray | White |

Mixing ratio(%) | 1 | 1 |

Viscosity (Pa.s) | 2.5±0.5 | |

Pot life in 25°C(min) | 60~90 | |

Curing time(min) | 180 in 25°C or 20 in 80°C | |

Hardness (shore A°) | 55±5 | |

Volume resistivity (Ω) | ≥1.0×1015 | |

Dielectric constance(1.2MHz) | 3.0~3.3 | |

Dielectric strength (kv/m-1) | ≥25 | |

Temperature resistance (°C) | -60~200 | |

Flame retardant | UL94-V1 | |

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents