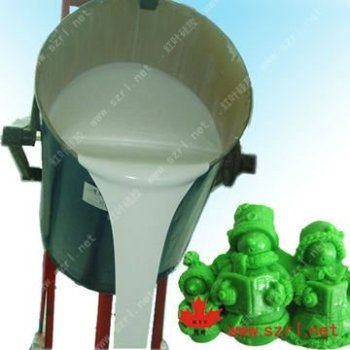

2 component addition cure silicone rubber for making high quality product

- US $11.48

200 - 40,000 kilogram

- US $9.98

40,001 - 999,999 kilogram

group nameAddition cure silicone rubber

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY-E6

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 16:54:25 GMT

Paramtents

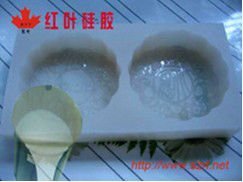

Color translucent

curing agent 1:1

Certification SGS,MSDS,RoHS

Material 100% silicone

Classification Chemical Auxiliary Agent

Appearance Fluid

Appliacation mold making

Port shenzhen

Sample free

Packging & Delivery

Min Order200 kilogram

Briefing

GRC and Concrete moulding

PU resin casting and gerneral molding

Detailed

Key words:

addition cure silicone rubber,addition cure silicone, food grade silicone addition, liquid rtv-2 silicone rubber, liquid addition silicone rubber

1.Applications of addition cure silicone rubber:

Addition cure silicone rubber is mainly used for metallic arts & crafts, baby nipples, cakes, candy food grade products mould making, life casting, medical catheter and so on.

2. Brief description of addition cure silicone rubber:

Addition cure silicone rubber is mainly used for metallic arts & crafts, baby nipples, cake, candy food grade products mould making, medical catheter and so on. It is nontoxic and with very low shrinkage.

3.Features of addition cure silicone rubber:

a) Two-component silicone rubber with platinum catalyst.

b) With high transparency, tensile strength, and tear strength.

c) Nontoxic & reach to Food grade.

d) With good heat stability and weatherability ( temperatureresistant range of -60---250 C).

e) With heat-ageing resistanc

E-series 2 component addition cure for making high quality product standard datasheet (25°C)

(The mixing ratio of part A and part B can be adjusted to 1:1or 10:1)

Product | E-615 | E-620 | E-625 | E-630 | E-642 |

Appearance | Translucent | Translucent | Translucent | Translucent | Translucent |

Hardness(shore A) | 15±2 | 20±2 | 25±2 | 30±2 | 40±2 |

Mix ratio(A:B) | 1:1 | 1:1 | 1:1 | 1:1 | 10:1 |

Viscocity Part A(mPa.s) | 9000±2000 | 11000±2000 | 15000±2000 | 20000±2000 | 55000±2000 |

Viscocity Part B(mPa.s) | 1900±500 | 1900±500 | 1800±500 | 2400±500 | 150±50 |

Tensile strength (MPa) | 6.2 | 6.5 | 6.7 | 7.2 | 7.6 |

Tear-strength (kN/m) | 25 | 26 | 23 | 24 | 22 |

Elongation(%) | 569 | 581 | 480 | 440 | 450 |

Density | 1.05 | 1.05 | 1.07 | 1.13 | 1.14 |

Pot life/working time (mins) | 30-40 | 30-40 | 30-40 | 30-40 | 30-40 |

Curing time/setting time (hrs) | 3-4hrs(25°C) 120-30mins(60°C) | 3-4hrs(25°C) 120-30mins(60°C) | 3-4hrs(25°C) 120-30mins(60°C) | 3-4hrs(25°C) 20-30mins(60°C) | 6-8hrs(25°C) 30-50mins(60°C) |

Shrinkage rate (%) | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

Need any help on silicone rubber, please feel free to contact Ms Kitty:

Tel:86-755-89948294

Mob:86-15989267535

E-mail: hysh(at)szrl(dot)net

Skype:kity-467707861

You need a product

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents