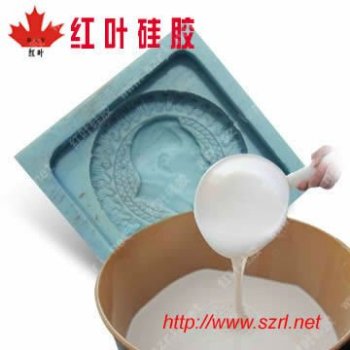

Silicone Rubber (RTV-2) for Mold Making

- US $7.60

200 - 40,000 kilogram

- US $5.50

40,001 - 999,999 kilogram

group nameAddition cure silicone rubber

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelHY-728#Silicone Rubber (RTV-2) for Mold Making

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 17:04:27 GMT

Paramtents

model Silicone Rubber (RTV-2) for Mold Making

Standard RoHS, SGS, MSDS

HS Code 39100000

sample free

color white/blue and so on

Export Markets worldwide

Packging & Delivery

Min Order200 kilogram

Briefing

2. high reproduction times

3. good tensile strength

4. exceptional fluidity

Detailed

Product Description

Silicone Rubber (RTV-2) for Mold Making application:

Silicone rubber is mainly used in mold making for the manufacturer of products made of unsaturated resin, epoxy resin, polyurethane, cultural relic duplication, architectural decoration, resin crafts, lighting ornaments, candles, statues, model design, product exploitation etc. HY-638 is good for mold making of fine and complex products, HY-788 is good for mold making of large and simple products.

Silicone Rubber (RTV-2) for Mold Making Features:

(1)With SGS and RoHS approval

(2)Curing agent arrange together as free charged

(3)In liquid form and in various colors

(4)With an exceptional fluidity and good operability.

(5)Temperature and deformation resistance as well as low Shrinkage.

(6)High duplication times.

(7)Samples are available

ilicone rubber (RTV-2) for mold making 728#:

Hardness(A): 22~24

Tensile strength (kgf/cm) ≥ 32

Tear Strength (kgf/cm) ≥ 20

Elongation break: (%)≥ 500

Retractility (%): ≤ 0.3

Curing agent mixed rate(%): 2-3

Operate time(min): 30

Curing time(hours): 2-4

Using instruction:

Component A is white flowing liquid and component B is the curing agent. For example, take silicone rubber of 100g and add 2g curing agent for mixing evenly (silicone rubber and curing agent must be measured accurately). After the silicone rubber and the curing agent are completely mixed, put the silicon into a vacuum machine for deairing to remove the bubbles. After deaired, pouring the liquid silicone rubber into the product to be duplicated or into the mold frame. If you don't have vacuum machine, please add 1.2% or 1.5% curing agent so that the bubbles can bubble itself. Since the less curing agent you add, the slower the mould will curdle, the bubbles will bubble out itself.

Any questions of silicone rubber for mold making, please feel free to contact Apple:

86-15889446131

eilen(at)szrl(dot)net

You need a product

Related Searches

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents