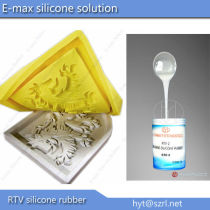

Addition Cure Type Silicone Rubber

- US $12.60

200 - 40,000 kilogram

- US $9.50

40,001 - 999,999 kilogram

group nameAddition cure silicone rubber

-

Min Order200 kilogram

brand nameHong Ye silicone rubber

modelRTV silicone EME615#

payment methodT/T, L/C, Westem Union

-

update timeFri, 08 Nov 2013 17:25:51 GMT

Paramtents

Color Translucent

Mixing ratio 1:1 simple mix

Hardness Shore A 15

Certificate FDA

Application make insole,foot care insole

Working time 30-50mins

Demould time 4-6 hours

Packing 25kg/pail

Shelf life 12 months

MOQ 100KG

Packging & Delivery

Min Order200 kilogram

Briefing

2.for Mold making

3.1:1 simple mix

3.Low shrinkage

4.FDA certificate

Detailed

| Addition Cure Type Silicone Rubber |

Platinum-Cure Silicone Rubber are generally named as two-part addition silicone rubber that vulcanises at room temperature.Part A is a flowable liquid, part B is the curing agent(platinum catalyst). It features an exceptional fluidity ,good operability,excellent physical properties and very low shrinkage. The mixing ratio between Part A and Part B can be 10:1 or 1:1.

| Appilications of Addition Cure Type Silicone Rubber |

Especially suitable for silicone insole,foot care insole

| Feactures of Addition Cure Type Silicone Rubber |

/FDA certificate,no toxicity.

/Good fluidity and good operability and good for pouring method.

/Excellent mechanical properties, in particular tear strength and tensile strength.

/Excellent flexibility

/High temperature resistance, high duplication times and repeated use.

| How to use Addition Cure Type Silicone Rubber |

1.The cast pouring, for example:

Prepare a frame, fix the prototype for copy into the frame, (if the prototype’s material is glass or ceramic, the release agent is necessary to prevent sticking.

2. Take 1 part A and 1 part B,mix themevenly.

3.Vacuum defoaming in 1~3 min,inject the rubber into the type box, then vacuum defoaming again, curing 24 hours in nature room temperature, use it after demold.

4. Demold after 3 hours’ room temperature curing, and then use it after 24 hours’ keep mold under the same condition.

| How to make a perfect silicone insole with Addition Cure Type Silicone Rubber |

Firstly,the silicone rubber and catalyst must be mix evenly,mixing for 5-6 minutes,if you do not mix evenly,it will cause one part is dry but other part is wet.

Secondly,if you have a vacuumed machine,that's will be perfect, vacuuming mixed silicone for 5-6 minutes,there will not have bubble.

Thirdly,the silicone mould need 24 hours to complete dry,so when you finished the silicone mould,please after 24 hours later bring into production.

I believe that the silicone mould will be perfect if you pay attention to these points.

| Delivery/Postage/Payment |

CERTIFICATION:

ISO9001: HK05/01358

SGS:GZ0606100461/CHEM

RoHS:BTRS091718751

Patent:ZL200520001597.8

Delivery terms:FOB,CFR,CIF

Exchange rate:1USD=6.20RMB

Packing:5kg/pail,25kg/pail,200kg/pail

Delivery time is within 3 days after getting your bank receipt.

Payment Terms: T/T 100% in advance,L/C,Western Union

Mind order quantity(MOQ):100KG

Transport: by sea or by air

Shelf life:12 months under room temperature not open

| Customer Satisfaction |

For getting further information about RTV-2 silicone rubber, PLS contact with

Ms Moe

Email: hyt(at)szrl(dot)net

Skype: moe.chai

Tel: 86-755-89948019

Mob: 86-13243825997

Web: ..........net

You need a product

Related Searches

You May Like

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents